PLASTIC BELT CONVEYORS

Applications

- Product transport through packaging lines

- Accumulation and buffering between processes

- Inclined conveying of cartons or components

- Curved routing around equipment

- Handling of small parts, containers, and packaged goods

Industries

- Food and beverage processing

- Packaging and labeling

- Manufacturing and assembly

- Plastics and molded products

- Pharmaceutical and personal care

- Distribution and material handling

Plastic belt conveyors are modular conveying systems that use interlocking plastic belt segments driven by sprockets to transport products along a defined path. The belt design provides a continuous, stable conveying surface with consistent tracking and controlled movement. These conveyors are commonly used where cleanliness, product support, or layout flexibility is required, including straight runs, curves, inclines, and declines.

Plastic belt conveyors operate by engaging molded belt modules with drive sprockets mounted on a powered shaft. The modular construction allows sections to articulate through curves and elevation changes while maintaining belt integrity. Belt styles and surface profiles are selected based on product geometry, orientation control, and environmental conditions such as moisture, debris, or washdown exposure.

These conveyors are frequently integrated into automated production and packaging systems where precise product handling is required. Configuration options include friction top surfaces for accumulation, grid styles for drainage or airflow, raised ribs for tracking, and roller top designs for multi directional product movement.

PPF | Flat Top Plastic Belt Parts Conveyor With Flights

The PPF flat top plastic belt parts conveyor with flights is engineered to convey small parts and components using a flat polypropylene belt fitted with streamline flights. Supports containment and positive tracking of small items during incline or horizontal conveying.

700PB | Friction Top Plastic Belt Conveyor

The 700PB plastic belt conveyor features a flat friction top belting surface designed to transport goods across straight sections or slight inclines. This friction surface maintains product position without the need for cleats, making it suitable for handling cartons, totes, and boxed goods during general conveying tasks.

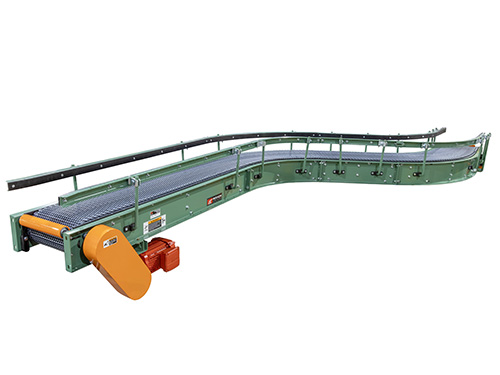

700PBC | Flush Grid Plastic Belt Curve Conveyor

The 700PBC flush grid plastic belt curve conveyor is engineered for conveying products through curved paths at defined angles, such as 30, 45, 60, or 90 degrees. Its flush grid belt provides airflow and drainage through the belt surface while maintaining product support, making it suitable for turns in packing or assembly lines.

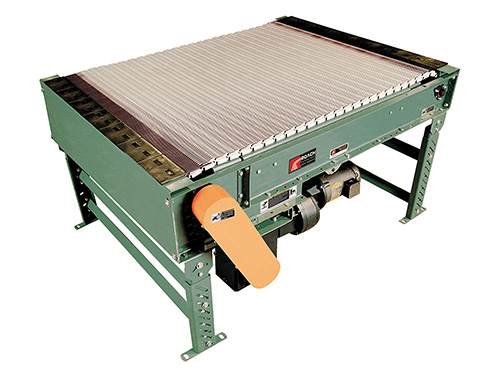

700FFT | Flat Friction Top Plastic Belt Conveyor

The 700FFT flat friction top plastic belt conveyor uses modular plastic belting with a friction top surface to move products with controlled grip and consistent tracking over straight or inclined paths. It is suited for handling cases, cartons, or loose items where slippage could occur during incline or decline conveying, and provides a stable conveying surface with minimal belt tracking issues.

700RR | Raised Rib Plastic Belt Conveyor

The 700RR raised rib plastic belt conveyor uses a belt with elevated ribs to help stabilize products that may otherwise shift or topple during movement. Raised ribs provide lateral control of small or unstable items such as bottles, cans, or small parts, improving alignment and reducing misalignment events.

700RT | Inline Roller Top Plastic Belt Conveyor

The 700RT inline roller top plastic belt conveyor integrates roller elements within the belt surface to support product movement and low back pressure accumulation. The combination of modular belt and embedded rollers enables accumulation without excessive resistance, reducing product stress on assembly lines or workstations.

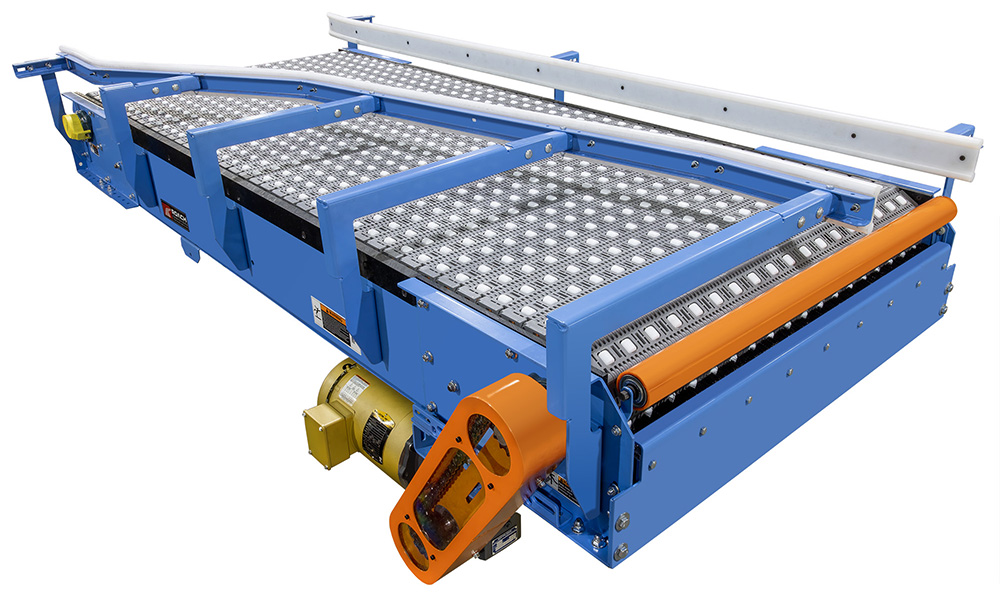

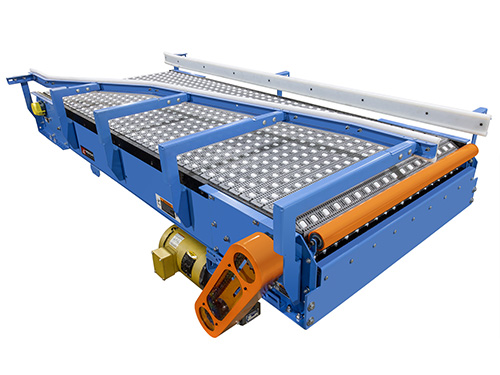

700TRT | Transverse Roller Top Plastic Belt Conveyor

The 700TRT transverse roller top plastic belt conveyor adds rollers mounted across the belt surface to facilitate product transfer at right angles or to aid box turning and centering. This configuration allows items to be diverted from or merged onto conveyors with reduced friction and improved alignment.

HD1200PB | Heavy Duty Plastic Belt Conveyor

The HD1200PB is a heavy duty plastic belt conveyor designed for the most demanding conveying tasks, including transporting footed pallets, large rolls, drums, and containers that typical roller conveyors cannot handle. It uses Series 1200 flat top belting to support extra heavy loads with positive engagement and minimal belt tracking issues.

400PB | Heavy Duty Plastic Belt Conveyor

The 400PB heavy duty plastic belt conveyor uses Series 400 flat top belting to move heavier unit loads that may not be suited to standard conveyor designs. Flat top modular belt provides a continuous and stable surface for larger parcels, crates, or partially assembled units where rigid support is necessary.