POWERED ROLLER CONVEYORS

Applications

- Carton and tote conveying

- Accumulation and buffering between processes

- Sortation and routing operations

- Order fulfillment and distribution

- Packaging and labeling lines

Industries

- Distribution and warehousing

- E-commerce and fulfillment

- Manufacturing and assembly

- Packaging operations

- Logistics and material handling

Powered roller conveyors, often referred to as motor driven roller or MDR conveyors, use individually powered rollers to move cartons, totes, and packaged goods through controlled conveying zones. Each roller contains a low voltage 24V motor that drives product movement without the need for external line shafts or chains. Rollers are activated only when product is present, allowing precise control of product flow and spacing.

These conveyors operate using zone based logic, where sensors detect product presence and signal individual rollers or roller groups to start or stop. Powered roller accumulation configurations support zero pressure accumulation by holding products in separate zones without contact. Poly-V band options can be used to transmit power from driven rollers to adjacent rollers, increasing torque and supporting higher speed applications or heavier loads.

Powered roller conveyors are commonly integrated into automated material handling systems where control, efficiency, and modular layout are required. Straight sections, curves, and merges can be combined to support complex conveyor paths while maintaining consistent product orientation and spacing.

796PRA | Powered Roller Zero Pressure Accumulating Conveyor

The 796PRA applies a similar powered roller accumulation concept to a larger bed design, using 24 V roller motors with rollers set low in a 7-inch formed steel channel frame. Zone singulation accumulation is photoeye actuated over standard zone lengths, and precision bearings ensure smooth roller motion.

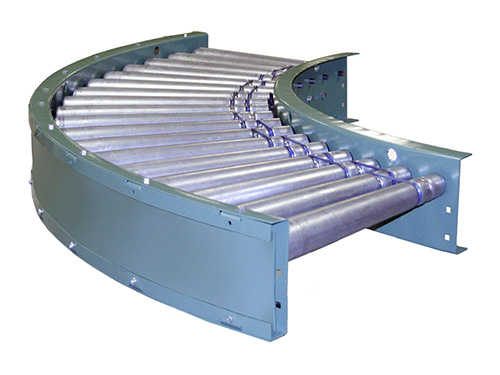

796PRAC | Powered Roller Accumulating Curve Conveyor

The 796PRAC configures the 796PRA into curved sections with tapered rollers and indirect drive logic, maintaining accumulation control through curves. Photoeye sensors actuate zones to stop and start product movement, supporting controlled queuing through non-linear layouts.

596PRA | Powered Roller Zero Pressure Accumulating Conveyor

The 596PRA powered roller accumulator uses 24 V motorized rollers to move cartons, totes, and unit loads while eliminating drive belts, chains, and line shafts. Rollers are set high in a 5-inch, formed steel channel frame, and accumulation is controlled through zone singulation with photoeye actuation.

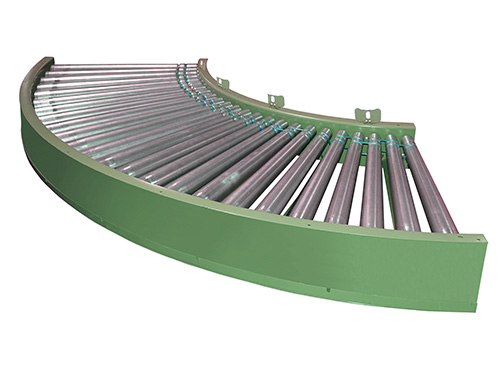

596PRAC | Powered Roller Accumulating Curve Conveyor

The 596PRAC extends the 596PRA’s zero pressure accumulation into curved layouts, using tapered rollers and motorized drive logic to maintain product movement through bends. It retains zone singulation operation with photoeye control, allowing products to queue in curved sections as needed without physical contact.

796PRA-2PV & 796PRA-3PV | Poly-V Powered Roller Accumulating Conveyor

The 796PRA-2PV and 796PRA-3PV incorporate Poly-V belt drives into the larger 796PRA platform, enhancing power transfer through belt adhesion across multiple rollers. These drive bands increase torque for higher load capacity per zone while maintaining the zero pressure accumulation operation.

596PRA-2PV & 596PRA-3PV | Powered Roller Accumulating Conveyor

The 596PRA-2PV and 596PRA-3PV configurations build on the standard 596PRA by adding Poly-V belt drives that transmit power to adjacent rollers through lengthwise belt grooves. Poly-V results in increased torque transfer and higher per-zone capacities.