GRAVITY CONVEYORS

Applications

- Order picking and pack stations

- Carton and tote flow between process steps

- Truck loading and unloading

- Accumulation and staging areas

- Manual inspection or assembly lines

- Pallet flow lanes in rack systems

Industries

- Distribution and fulfillment

- Manufacturing and assembly

- E-commerce fulfillment

- Food and beverage packaging

- Consumer goods

- Automotive and industrial supply

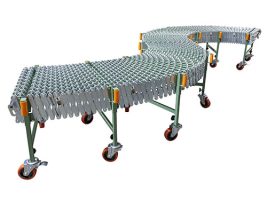

Gravity conveyors use rollers, wheels, rails, or ball transfer assemblies to move products without powered assistance. Loads advance manually or by gravitational force across a fixed frame, making gravity conveyor systems a practical choice for zones where controlled movement, accumulation, or transfer is required. These conveyors are commonly integrated into picking, packing, inspection, and shipping operations where simplicity and reliability are prioritized.

Gravity conveyor designs support a wide range of product sizes, weights, and bottom surfaces. Roller gravity conveyors accommodate cartons, totes, pallets, and irregular loads, while wheel conveyors are well suited for lightweight items and portable layouts. Rail wheel conveyors provide low profile flow paths for floor or rack mounted applications. Ball transfer conveyors allow omnidirectional movement for workstations that require frequent repositioning of products.

Gravity conveyors are typically modular and configurable, allowing straight runs, curves, merges, and declines to be arranged around existing equipment and facility constraints. Material options, frame construction, and duty ratings can be matched to environmental conditions and load requirements across distribution, manufacturing, and assembly operations.