ACCUMULATION CONVEYORS

Applications

- Product buffering between processes

- Merging and singulation of cartons or totes

- Accumulation before sortation, labeling, or inspection

- Controlled release into packaging or palletizing equipment

- Staging product for shipping and order fulfillment

Industries

- Distribution and fulfillment operations

- Manufacturing and assembly lines

- Packaging and material handling systems

- Food and beverage processing

- Automotive and industrial manufacturing

Accumulation conveyors are used to manage product flow by allowing items to queue, stop, and release along a conveyor line without interrupting upstream operations. These systems divide the conveyor into individual zones that operate independently, enabling controlled accumulation when downstream equipment pauses or operates at a different rate. Accumulation conveyors are commonly applied in systems where product spacing, orientation, and controlled release are required.

Accumulation can be achieved through mechanical pressure or zero pressure zone control. Zero pressure accumulation prevents product to product contact by stopping each zone independently, reducing the risk of damage and improving handling consistency. Smart Zone® is a zero pressure accumulation technology that uses smart photo eyes rather than pressure rollers to detect product presence. Smart Zone® replaces sensor rollers with photoelectric sensors, allowing accumulation of products with minimal or inconsistent weight and eliminating the need for a weight minimum to activate each zone. This design supports cartons, totes, and pallets that are lightweight, uneven, or difficult to sense using traditional roller based systems and is designed for straightforward installation.

Accumulation conveyors are available in multiple configurations to match load requirements, product types, and operating conditions. Common designs include chain driven live roller, line shaft, powered roller, and heavy duty models for higher capacities. These conveyors are frequently integrated with merges, diverts, transfers, and automated controls to support complex material handling layouts.

196ZPA | Zero Pressure Accumulator Medium Duty Conveyor

The 196ZPA medium duty zero pressure accumulator conveyor employs pneumatic zone singulation to control product flow without causing back pressure on upstream units. This conveyor safely accumulates products by stopping individual zones while allowing live rollers at each end to maintain motion, supporting loads up to approximately 125 pounds per foot with standard roller and drive configurations.

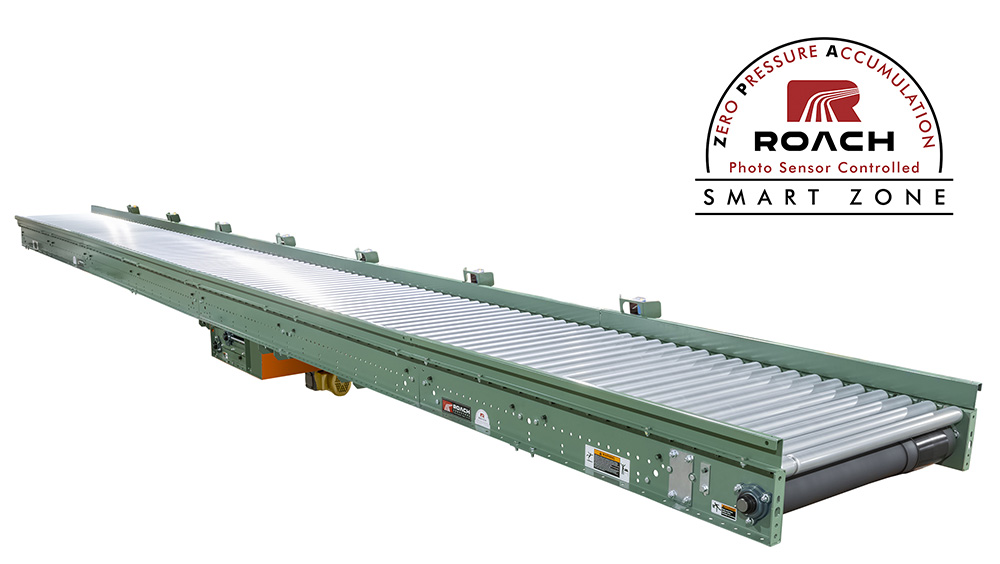

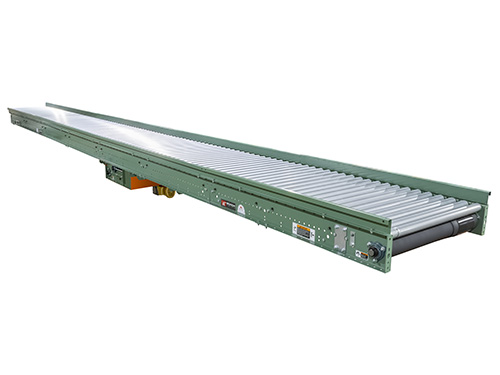

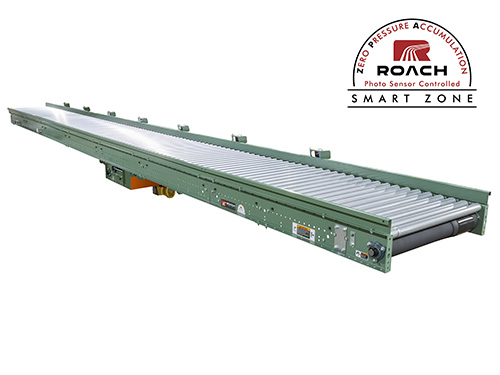

SZ196ZPA | Zero Pressure Accumulator Smart Zone® Medium Duty Conveyor

The SZ196ZPA applies Smart Zone® proprietary photoelectric sensing for zero pressure accumulation, replacing traditional sensor rollers with photo eyes to detect product presence without requiring a minimum load weight. This medium duty accumulator safely queues cartons, totes, and similar packages using zone singulation while eliminating back pressure, extending reliable accumulation to products that may not engage roller-based sensors effectively.

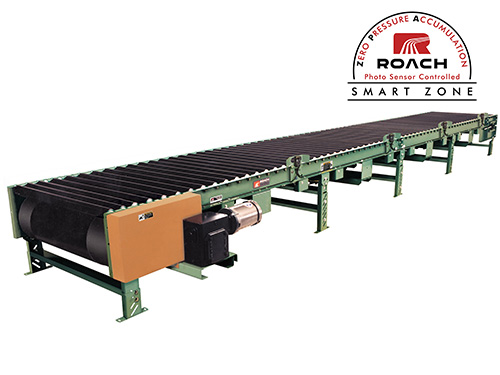

SZ251ZPA | Zero Pressure Accumulator Smart Zone® Heavy Duty Conveyor

The SZ251ZPA heavy duty Smart Zone® accumulator is engineered to manage significantly higher loads, accommodating heavy containers, large boxes, and palletized units using zero pressure zone singulation. Photoelectric sensors replace sensor rollers, enabling each accumulation zone to detect product presence without minimum weight limitations and preventing contact between queued products.

SZ796LSZ | Line Shaft Zero Pressure Accumulator Smart Zone® Conveyor

The SZ796LSZ combines zero pressure accumulation with a line shaft driven design that supports light to medium duty operations. Smart Zone® photoelectric sensors detect product presence for zone singulation without requiring a minimum product weight, allowing a wide variety of package sizes and formats to accumulate without back pressure.

SZA192CDA | Chain Driven Zero Pressure Accumulator Smart Zone® Medium Duty Conveyor

The 796RB roller bed belt conveyor balances increased carrying capacity with the economy of a belt conveyor by introducing a roller support structure beneath the belt. This reduces friction and enables more consistent movement of medium duty products with lower horsepower requirements than typical slider designs.

SZA251CDA | Chain Driven Zero Pressure Accumulator Smart Zone® Heavy Duty Conveyor

The SZA251CDA heavy duty chain driven Smart Zone® accumulator extends the benefits of zero pressure accumulation to heavier unit loads and more demanding conditions. Photoelectric sensors manage zone detection without minimum weight activation, while chain drive mechanics deliver robust traction across broader loads and extended run lengths.

SZD192CDA | Chain Driven Zero Pressure Accumulator Smart Zone® Medium Duty Conveyor

The SZD192CDA medium duty chain driven zero pressure accumulator uses Smart Zone® sensing to detect product presence and control accumulation without requiring back pressure or minimum product weights. Zone singulation ensures products queue individually, reducing contact and improving handling consistency for mixed and medium duty product lines.

SZD251CDA | Chain Driven Zero Pressure Accumulator Smart Zone® Heavy Duty Conveyor

The SZD251CDA heavy duty chain driven zero pressure accumulator extends Smart Zone® photoelectric sensing to heavy load environments, supporting larger pallets and dense products without requiring minimum weight engagement. Zone singulation with photo sensors prevents back pressure and product contact while enabling heavy duty accumulation operation in demanding material handling systems.