TURNTABLES

Applications

- Pallet reorientation at merge or transfer points

- Directional changes between perpendicular conveyor lines

- Load positioning for automated processing or storage

- Accumulation and release control in pallet handling systems

- Transitions within space-limited conveyor layouts

Industries

- Warehousing and distribution

- Manufacturing and assembly operations

- Food and packaged goods handling

- Automotive and industrial products

- Material handling and logistics facilities

Turntable conveyors are used to reorient loads within a conveyor system by rotating packages or pallets to a new direction of travel. These units support controlled product transfer at intersections, merge points, and layout transitions where straight conveying alone cannot meet system requirements. Turntables are commonly integrated into pallet handling and unit load systems to manage directional changes while maintaining load stability and alignment.

Two primary configurations are used in industrial applications: continuous rotation turntables and indexing turntables. Continuous rotation turntables rotate while the load remains in motion, making them suitable for applications requiring uninterrupted product movement. Indexing turntables rotate in defined increments and stop precisely at programmed positions, allowing accurate alignment with infeed and discharge conveyors. Heavy duty designs are capable of handling pallet loads up to 5,000 pounds and can be configured with powered roller, chain drag, belt, or modular conveyor surfaces depending on load type and system demands.

Turntable conveyors are engineered to integrate with upstream and downstream equipment and are often selected where space constraints, product orientation control, or system flexibility are required. Optional surfaces such as non-marking cross or grid tables support specialized handling needs and product protection.

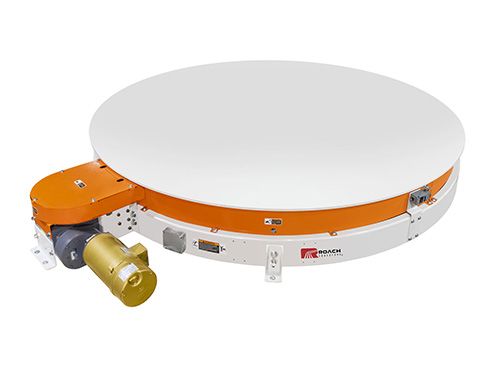

CRT | Continuous Rotation Powered Turntable Medium Duty

The CRT continuous rotation powered turntable is designed to rotate unit loads through a full 360-degree sweep while conveying in tight spaces where large radius curves cannot be placed. Continuous rotation allows loads to remain in motion during orientation, which simplifies conveyor system layouts that require directional changes within confined footprints.

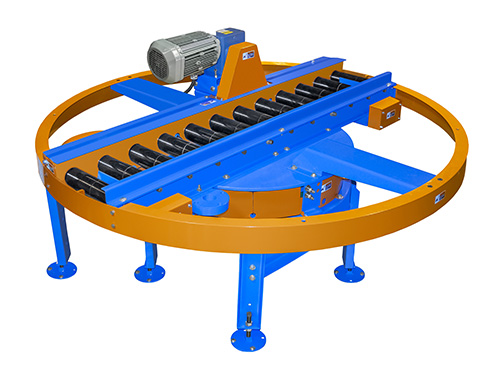

IPT | Indexing Powered Turntable Heavy Duty

The IPT indexing powered turntable rotates heavy unit loads in discrete positional increments, enabling precise orientation for subsequent processing or routing. The turntable platform can be fitted with a heavy duty chain driven live roller or other conveyor modules to support load transfer and rotation at defined stops, which aids in loading, unloading, or inspection tasks.

Grid Turntables

Grid turntable employs a low elevation grid surface to support loads during rotation. Product is positioned on the grid, lowered, rotated manually up to 90 degrees, and then raised back onto adjoining conveyor sections.

Specialty Turntables

Special Application Turntables are often equipped with top-mounted modules that expand functionality and allow integration with conveyors, fixtures, or handling devices. These modules are selected based on product type and process needs, enabling turntables to serve as transfer points.