SPECIALTY TURNTABLES

Special Application Turntable conveyors are engineered to rotate products within material handling systems that require capabilities beyond standard turntable designs. These units are built for heavy duty operation and support controlled rotation for product orientation, positioning, and transfer. Powered turntables may operate in continuous rotation or indexing modes, allowing them to align loads with downstream conveyors or process equipment while maintaining predictable movement.

Heavy duty turntables used in special applications are designed to support high load capacities, irregular product shapes, and demanding operating conditions. Construction and drive components are selected to provide stable rotation and long service life in industrial environments. Rotation angles, speeds, and control logic can be configured to match system requirements, supporting both constant motion and precise stop-and-position operation.

Special Application Turntables are often equipped with top-mounted modules that expand functionality and allow integration with conveyors, fixtures, or handling devices. These modules are selected based on product type and process needs, enabling turntables to serve as transfer points, orientation stations, or positioning platforms within complex material handling layouts.

Applications

- Rotating loads to align with downstream conveyors or processing equipment

- Indexing products for controlled orientation during assembly or inspection

- Transferring heavy or irregularly shaped products between conveyor paths

- Positioning loads for robotic pick and place operations

- Changing product direction within tight or complex conveyor layouts

- Supporting fixture mounted parts during processing or staging

- Acting as controlled accumulation or buffer points in automated systems

Industries

- Heavy manufacturing and fabrication

- Automotive and transportation equipment

- Glass, solar, and panel processing

- Building materials and construction products

- Metals processing and foundry operations

- Industrial equipment manufacturing

- Warehousing and automated distribution systems

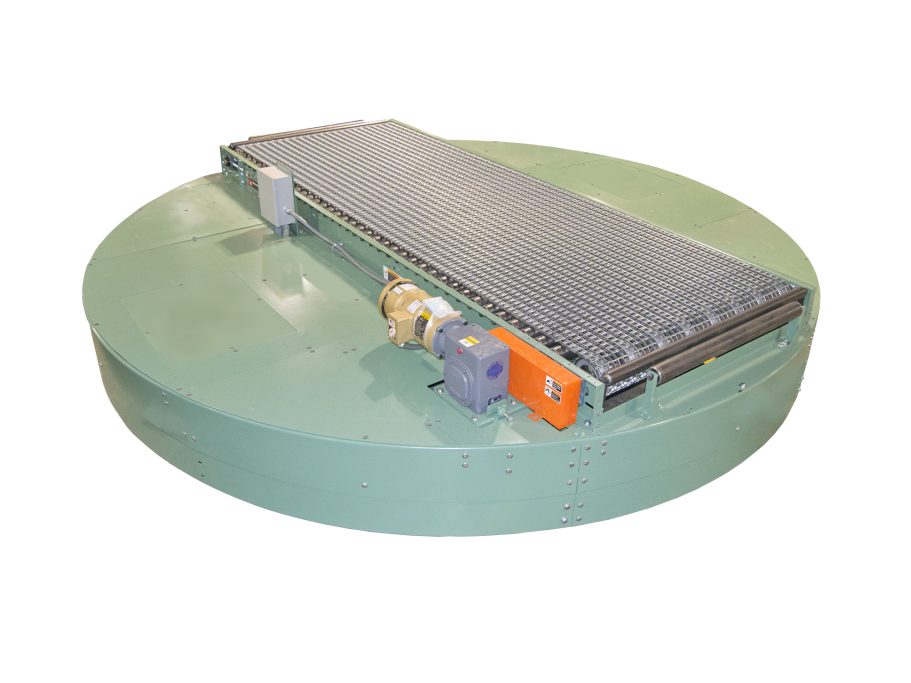

23' IPT | 60″ CDLR Module

This turntable was designed to rotate a 3500 lbs. product while workers are present. The 251 CDLR has a 5’ conveying surface with treadplates mounted between the rollers. These treadplates are alternating colors yellow and white on each end of the conveyor to help the operator center the product before rotating. The heavy duty center pivot turntable is a 23' in diameter with casters to support the outer ring.

ref#450287

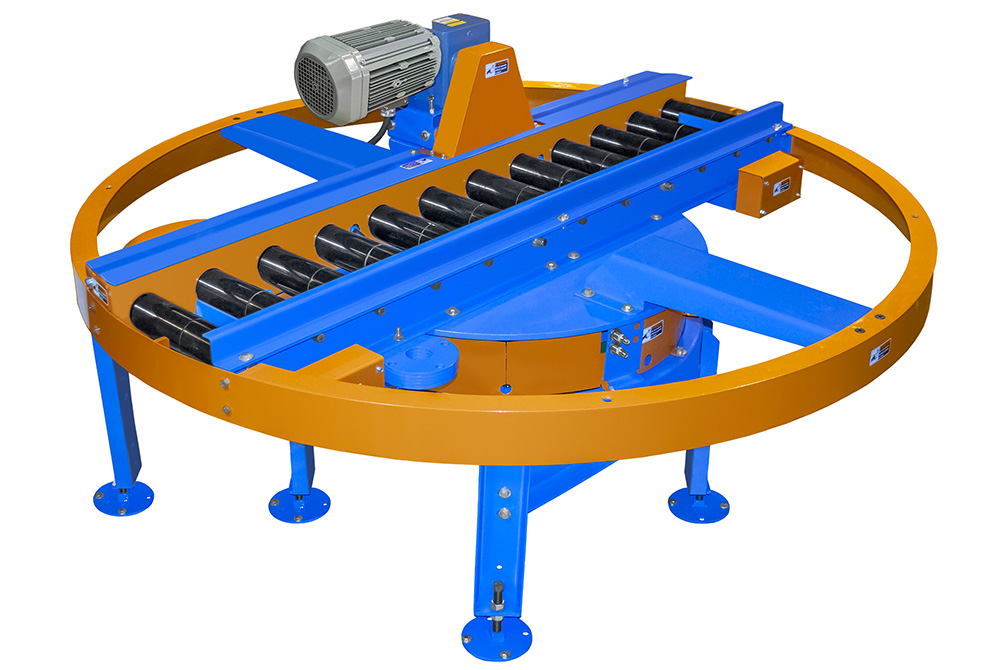

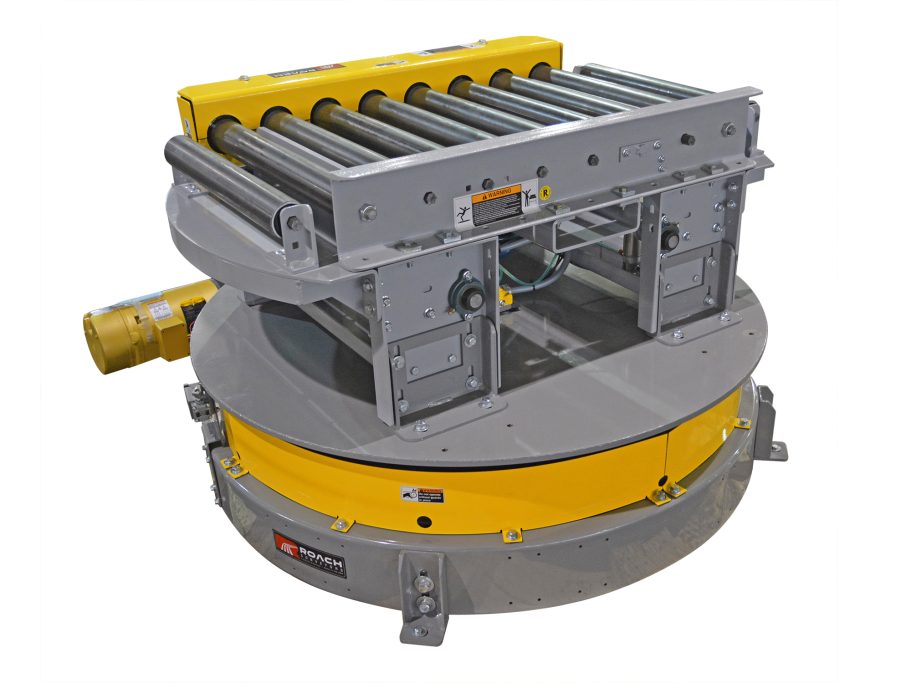

IPT | Dual Lane 3530 CDLR

The indexing powered turntable is designed to rotate heavy products with loads up to 5,000 pounds. Two lanes of 3530 CDLR conveyors with a 61 inch between-frame width are mounted on the 16 foot 9 inch diameter turntable, allowing controlled indexing and stable load support during rotation.

ref#490243