CONVEYOR TRANSFERS

Applications

- Right angle transfers between parallel conveyor runs

- Product routing to multiple downstream lines

- Pallet turning or reorientation within a conveyor cell

- Carton diverting in accumulation or sortation areas

- Controlled transfers in limited floor space layouts

Industries

- Manufacturing and assembly operations

- Distribution and fulfillment centers

- Packaging and converting facilities

- Food and beverage processing

- Consumer goods and industrial products handling

Conveyor transfers are used to redirect, merge, or divert product flow within a material handling system. Transfers operate by temporarily supporting a load and moving it perpendicular to the primary conveying direction, allowing products to change orientation or route without manual handling. Common configurations include 90 degree chain transfers, 90 degree v-belt transfers, and air controlled skate wheel transfers. Each design uses mechanical or pneumatic actuation to raise the transfer surface above the carrying conveyor, move the load, and then return to a lowered position once the transfer is complete.

These systems are typically integrated between live roller, belt, or chain-driven conveyors and are selected based on load stability, unit weight, bottom surface condition, and required transfer frequency. Chain transfers are well suited for rigid pallets and heavy loads, while v-belt transfers provide controlled side movement for cartons and totes. Air controlled skate wheel transfers are often used where low back pressure and gentle product handling are required. Properly applied, transfer conveyors support efficient line layout and controlled product routing in space-constrained environments.

Designed for industrial duty, conveyor transfers are built with robust frames, precision bearings, and drive components matched to the demands of continuous operation. Their modular nature allows them to be incorporated into new systems or retrofitted into existing conveyor lines with minimal disruption. Selection is typically driven by product characteristics, conveyor speed, and system control requirements.

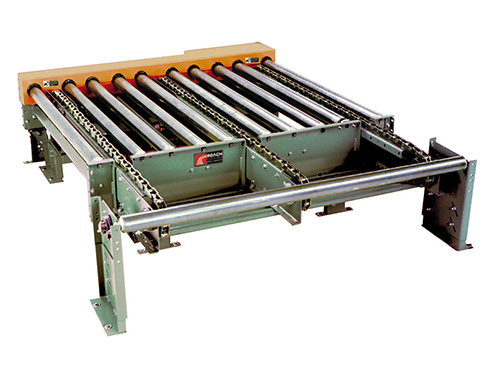

CT360 | 90° 3-Strand Chain Transfer

The CT360 90° 3-Strand Chain Transfer uses three parallel strands of flat side bar chain to move heavy unit loads at right angles between conveyor runs. Chain transfers are selected for applications where rigid pallets, crates, or other heavy packaged goods must be redirected in tight layouts that do not allow large radius turns. Each chain strand is supported by a formed transfer arm and driven by a gear motor to supply consistent motion for heavy duty handling.

CT380 | 90° 3-Strand Chain Transfer

The CT380 model shares the core design philosophy of the CT360 but uses a larger flat side bar chain for increased load capacity and rigidity in heavy duty material handling. Like CT360, the CT380 facilitates right angle redirection of pallets or unit loads where space constraints prevent the use of wide turning curves. The transfer arm and drive components are engineered to support high capacity operation and maintain alignment with the adjoining conveyor lines.

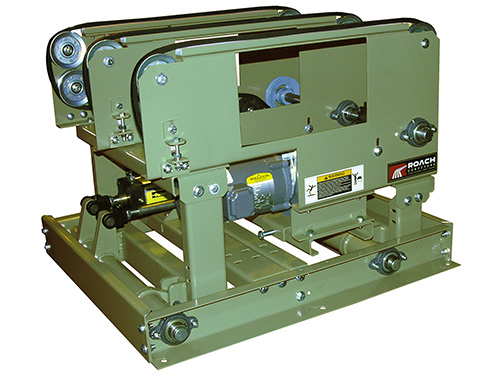

VBT3 | 3-Strand 90° Transfer V-Belt Conveyor

The VBT3 3-Strand 90° V-Belt Transfer Conveyor uses multiple “B” section v-belts mounted on a formed transfer arm to redirect medium duty products at right angles between conveyor runs. V-belt transfers are appropriate where product surfaces are delicate or may be marred by metal chain strands, providing a softer interface while maintaining controlled directional change.

WT3 | 3-Strand 90° Wheel Transfer with Positive Lift

The 3-Strand 90° Wheel Transfer is engineered to change product direction at right angles within a conveyor line by raising wheel strands above the conveyor surface to support and convey loads across an intersecting path. This transfer is designed for installation within the conveyor frame and uses pneumatic lift to position the wheel strands into the product path.