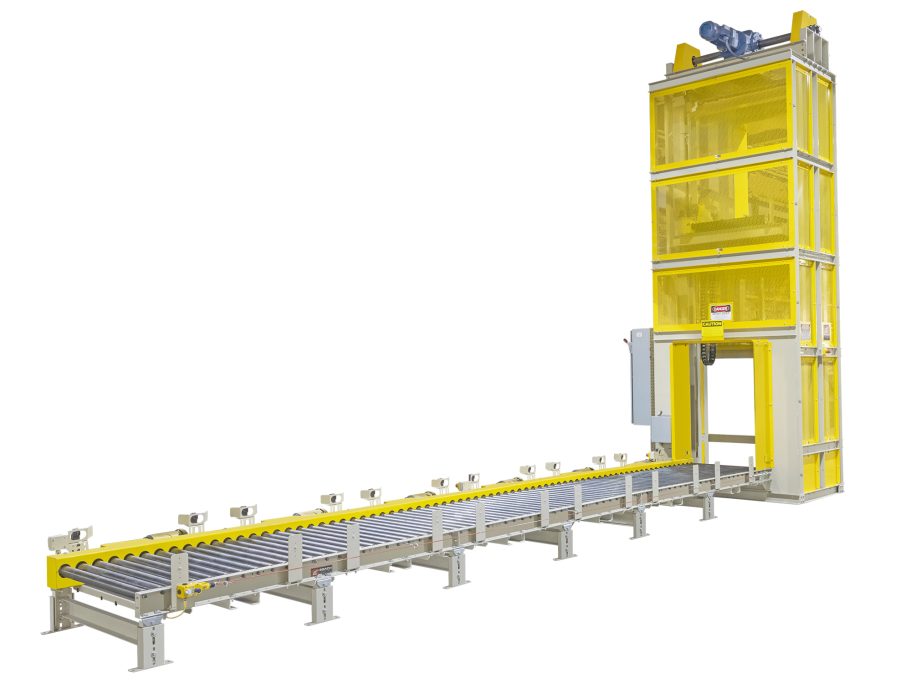

The Reciprocating Vertical Conveyor (RVC) transfers product between elevations using a lift platform and controlled reciprocating motion. In a C-Flow configuration, product enters and exits on the same side across two levels, following a C-shaped path that aligns with many traditional conveyor layouts and supports straightforward system integration.

In a Z-Flow configuration, product enters on one side and exits on the opposite side, creating a Z-shaped path that offers greater layout flexibility when conveyors are oriented differently. Both configurations provide precise load positioning and dependable vertical transport for applications where continuous motion is not required and space, timing, and integration are critical.

The added capability of reversible operation supports dynamic material routing within a facility, allowing the same vertical lift unit to service multiple flow paths or to adapt to changing operational requirements. The reciprocating platform ensures dependable placement and transition of loads between elevations.

Applications

- Floor-to-floor or mezzanine-to-floor material transfer

- Pallet and unit load elevation in limited floor space

- Feeding or discharging automated storage systems

- Vertical transitions within sortation or accumulation lines

- Process elevation changes in manufacturing or assembly operations

Industries

- Distribution and fulfillment operations

- Manufacturing and assembly facilities

- Warehousing and logistics centers

- Food and packaged goods handling

- Automotive and industrial products manufacturing

- E-commerce and order processing environments

Special Applications

- Cantilever RVC | A 400lbs. pallet with stacked product is loaded at the bottom of the vertical. The pallet is then lifted to the top section. As one layer of the product is removed the pallet is raised to unload the next layer until the pallet is empty. The empty pallet is then lowered and removed ready for the next loaded pallet. | ref#427911

SPECIFICATIONS

| CAPACITY | Up to 3000 lbs. |

| BED / FRAME | Heavy duty tubular construction. |

| DRIVE | (2) heavy strands of chain to raise and lower carrier platform. |

| MOTOR DRIVE | 1/2 HP, 230/460/3, 60 cycle, Super "E" right angle gear motor |

| RATE | Varies with unit height. |

| SPEED | 60 FPM (120 FPM maximum). |

| LOADING | One or more loading points may be selected at any level. |

| PLATFORM | Specify conveyor type. |

| GUARDS | Expanded metal guarding. |

| CONTROLS | Optional. |

DETAILS

ACCESORIES / OPTIONS

C-Flow Pattern

Z-Flow Pattern

Reversing Application

Guard Rails

Speed

Motors

Controls

WARRANTY

Electrical: 12 Months

Mechanical: 12 Months

SERVICES

Technical Support

Installation & Service

Preventative & Routine Maintenance

Application Support

Operator & Maintenance Training