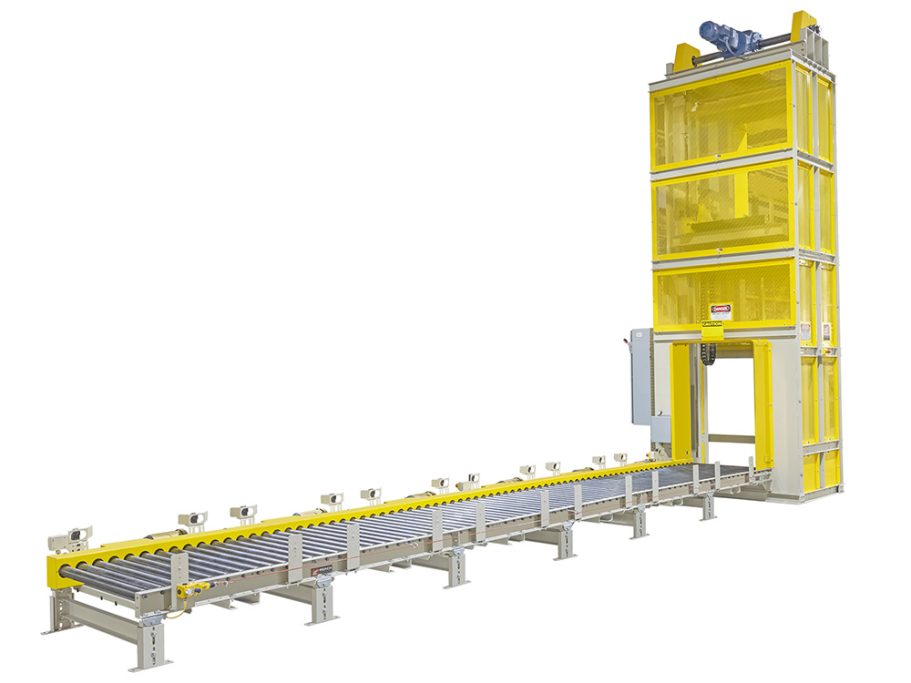

VERTICAL LIFT CONVEYORS

Applications

- Floor-to-floor or mezzanine-to-floor material transfer

- Pallet and unit load elevation in limited floor space

- Feeding or discharging automated storage systems

- Vertical transitions within sortation or accumulation lines

- Process elevation changes in manufacturing or assembly operations

Industries

- Distribution and fulfillment operations

- Manufacturing and assembly facilities

- Warehousing and logistics centers

- Food and packaged goods handling

- Automotive and industrial products manufacturing

- E-commerce and order processing environments

Vertical lift conveyors are engineered to move unit loads between elevations where conventional incline or decline conveying is impractical. These systems operate by lifting loads vertically in a controlled motion, either continuously or in a reciprocating cycle, allowing material to transition efficiently between floors, mezzanines, or process levels. Designed for heavy industrial use, vertical lift conveyors support package and pallet handling in space-constrained environments while maintaining predictable load control.

Available configurations include continuous vertical conveyors and reciprocating vertical conveyors, as well as C-flow and Z-flow layouts that accommodate specific infeed and discharge requirements. Reversible operation supports bi-directional movement, allowing a single system to serve multiple process paths. Heavy-duty I-beam construction enables lifting capacities up to 4,000 pounds, making these conveyors suitable for demanding applications that require durability, precision, and repeatable performance.

Vertical lift conveyor systems are commonly selected where floor space is limited, elevation changes are significant, or load stability is critical during vertical transfer. Their modular designs allow integration into new or existing conveyor systems across a wide range of industrial material handling environments.

RVC | Reciprocating Vertical Conveyor

The Reciprocating Vertical Conveyor (RVC) transfers product between elevations using a lift platform and controlled reciprocating motion.

CVC | Continuous Vertical Conveyor

The Continuous Vertical Conveyor (CVC) provides uninterrupted vertical transport using a series of carriers that move continuously to support higher throughput requirements.

PVC | Pneumatic Vertical Lift

The pneumatic vertical lift uses air-powered actuation to raise and lower loads between levels. Pneumatic systems offer a straightforward mechanical approach using compressed air to power the lift mechanism.