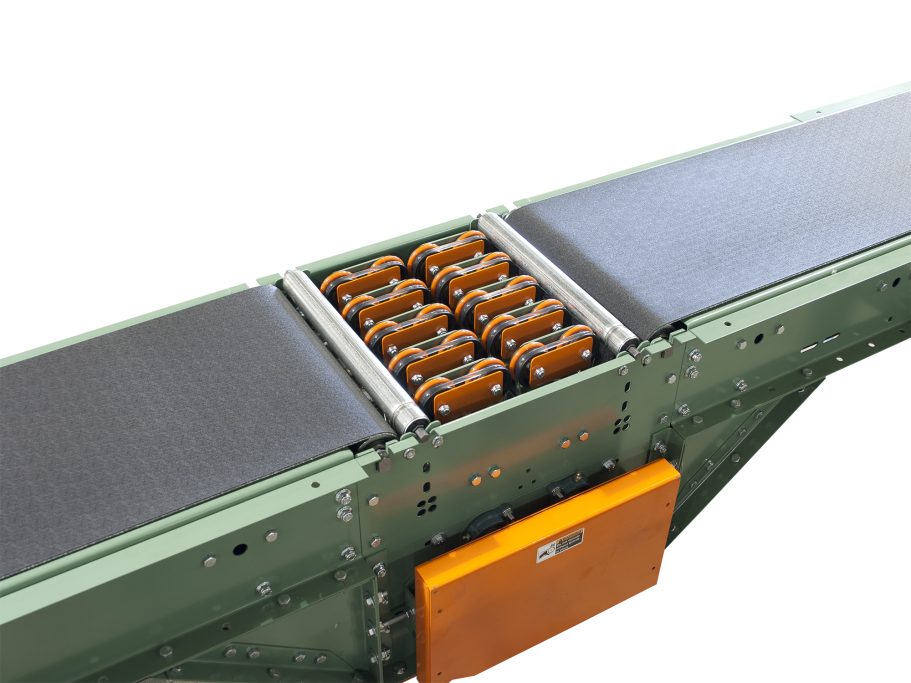

The 796 Sort Belt is a belt driven diverting conveyor designed for controlled, high rate package sorting in compact footprints. It uses a Trackmate belt supported by machine crowned pulleys to maintain belt tracking and consistent contact through the diverting zone. A fully lagged 8 inch diameter drive pulley with a 1-7/16 inch shaft provides reliable traction, while a crowned 4 inch tail pulley with screw take up allows up to 12 inches of belt adjustment to maintain proper tension. Maximum belt speed is 300 feet per minute, with operating speed dependent on product size, weight, and required sort accuracy.

Product diverting is accomplished through a staging diverter and dual pivoting wheel assemblies with urethane drive bands that are slave driven from the conveyor belt. Dual double acting air cylinders provide controlled actuation using a single solenoid with a 40 PSI air supply, allowing packages to be staged prior to diverting for consistent placement. The conveyor supports 30 degree and 45 degree diversion angles, includes a 2-1/2 inch diameter nose bar pulley for smooth discharge, and incorporates safety pop out rollers at both ends. With sorting rates up to 75 sorts per minute, the 796 Sort Belt is well suited for automated sortation applications requiring repeatable performance and straightforward mechanical integration.

Applications

- High rate package sortation to spur conveyors

- Diverting cartons, totes, and polybags to multiple takeaway lines

- Automated routing in pick, pack, and ship operations

- Product staging and controlled release prior to diverting

- Merge and divert points in compact conveyor layouts

- Order consolidation and zone based sorting systems

Industries

- E-commerce fulfillment and distribution

- Third party logistics operations

- Parcel handling and shipping centers

- Consumer packaged goods manufacturing

- Food and beverage packaging

- General warehousing and distribution centers

SPECIFICATIONS

| BELTING | Trackmate |

| DRIVE PULLEY | 8 in. dia. with 1-7/16 in. dia. shaft, machine crowned and fully lagged |

| TAIL PULLEY | 4 in. dia., machine crowned, with 1-3/16 in. dia. shaft |

| NOSE-BAR PULLEY | 2-1/2 in. dia. machine crowned pulley |

| TAKE-UP | Screw type unit at tail pulley provides 12 in. belt take-up |

| BELT SPEED | 300 FPM maximum; dependent on product size and weight |

| SAFETY POP-OUT ROLLER | Standard on both ends, 1.9 in. dia. x 16 ga. galvanized steel roller, model 196G |

| AIR CYLINDER | Dual, 1-1/16 in. bore x 1 in. stroke, double action cylinders |

| AIR CONTROLS | Single solenoid, 40 PSI required |

| DIVERTER | Dual pivoting wheels with urethane drive bands |

| DIVERTER DRIVE | Slave driven from the conveyor belt |

| DIVERSION ANGLE | 30° and 45°; guard rails on take-away spur conveyor may be required |

| RATE | Up to 75 sorts per minute |

| STAGING DIVERTER | Stages package for diverting |

DETAILS

ACCESORIES / OPTIONS

Floor Supports

Speed

Controls

WARRANTY

Electrical: 12 Months

Mechanical: 12 Months

SERVICES

Technical Support

Installation & Service

Preventative & Routine Maintenance

Application Support

Operator & Maintenance Training