LUMBER & DOORS

Lumber and door conveyors are used in wood processing and manufacturing environments to transport boards, panels, and finished door products through production and finishing operations. These systems support controlled movement of long, heavy, or rigid materials between cutting, machining, assembly, and packaging stations. Conveyor designs are selected to manage varying product lengths, widths, and weights while maintaining consistent spacing and alignment.

Conveyors used for lumber and door handling are typically built with heavy duty frames and conveying surfaces designed to withstand impact loading and abrasive conditions. Chain driven live rollers, belt conveyors, and specialty transfers are commonly used to support stable movement of stacked or single piece products. Speed control and conveyor configuration are matched to process requirements to support predictable flow through each stage of production.

Lumber and door conveyor systems are often integrated into larger material handling layouts that include accumulation zones, transfers, and direction changes. These systems are engineered to support continuous operation while reducing manual handling and improving organization across the production floor. Conveyor layouts are customized to accommodate facility constraints and product handling needs.

Applications

- Transporting lumber through cutting and machining lines

- Moving door panels between assembly stations

- Feeding materials into sanding and finishing equipment

- Accumulating products prior to packaging or palletizing

- Transferring loads between production zones

- Supporting infeed and discharge for automated machines

Industries

- Lumber and wood processing facilities

- Door and millwork manufacturing

- Building materials production

- Furniture and cabinet manufacturing

- Construction products manufacturing

- Industrial woodworking operations

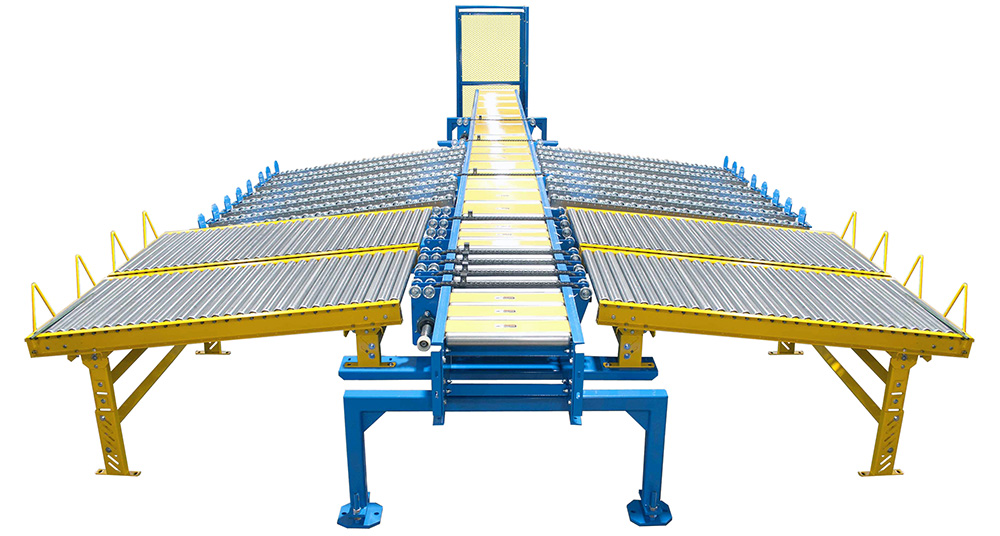

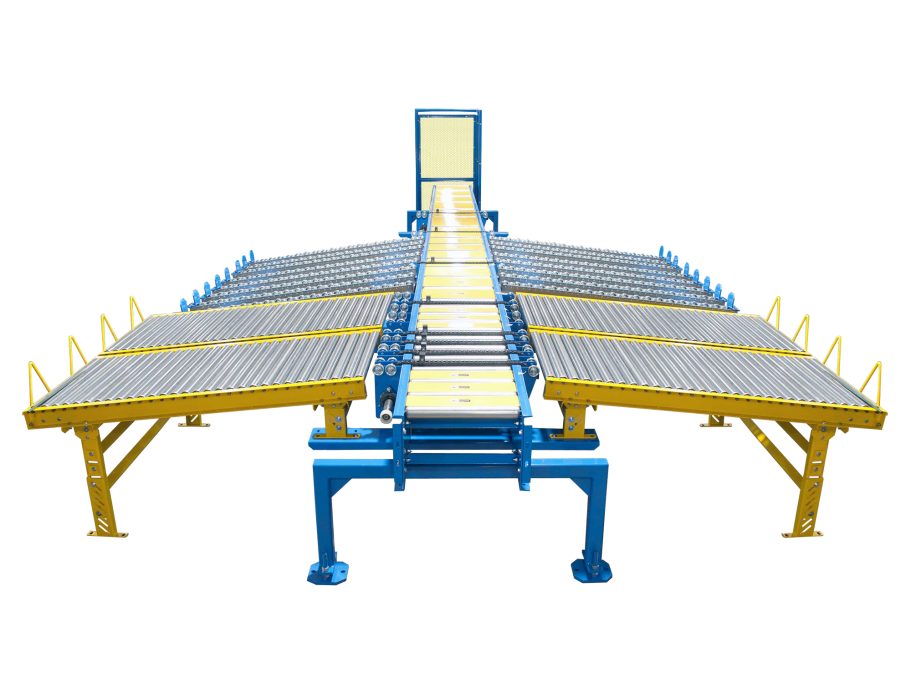

Puller Dog Lumber Transfer

Designed for the lumber industry, the Puller Dog Lumber Transfer is built to accept fresh cut boards of various lengths as they discharge from a high-speed saw. The Puller Dogs on the chains then transfer the boards off to either side onto gravity accumulation conveyors.

ref#478793

5-Strand Plastic Belt

This unit is designed to transport and accumulate plastic/fiber boards prior to an automated CNC router. As the boards are loaded on the conveyor they move forward and are staged along the length of the conveyor. Once the conveyor is fully loaded a pneumatic push-off advances the board 12” where it is automatically indexed forward into the router. After the board is placed in the router the next board can then index forward into the transfer area where it is staged.

Door Accumulator

This Poly-V conveyor has been designed to accumulate finished doors in several different heights and thicknesses. An 84” high triple channel style guard has been attached so that the doors can be conveyed in an upright position. To prevent damaging the finish the rollers have a PVC covering and the rails are lined with brushes.

ref#506580