LAUNDRY CONVEYORS

Laundry conveyors are used in commercial and industrial laundry facilities to transport carts, bins, and bulk textile loads between processing stages. These systems support material movement through washing, drying, sorting, folding, and staging operations where reliability, cleanliness, and durability are required. Conveyor layouts are designed to manage continuous operation in environments exposed to moisture, heat, lint, and cleaning chemicals.

Conveyor designs for laundry applications prioritize structural strength and consistent motion while accommodating varying load types and handling methods. Open deck and heavy duty constructions are commonly used to reduce debris buildup and support frequent washdown or cleaning. Conveyors can be integrated with automated equipment or manual handling stations to support predictable flow throughout the facility.

Laundry conveyor systems are typically engineered as part of a coordinated material handling layout rather than standalone components. Speed control, load capacity, and conveyor configuration are selected based on process requirements, available floor space, and operator interaction. These systems help organize material movement while reducing manual transport between work areas.

Applications

- Transporting laundry carts between processing areas

- Moving bulk linens to sorting and folding stations

- Feeding materials into washers, dryers, and finishing equipment

- Transferring loads between wash, dry, and pack zones

- Accumulation and staging of processed laundry

- Supporting organized material flow across the facility

Industries

- Commercial laundry operations

- Healthcare and hospital laundries

- Hospitality and hotel services

- Industrial uniform providers

- Correctional and institutional facilities

- Textile and linen processing operations

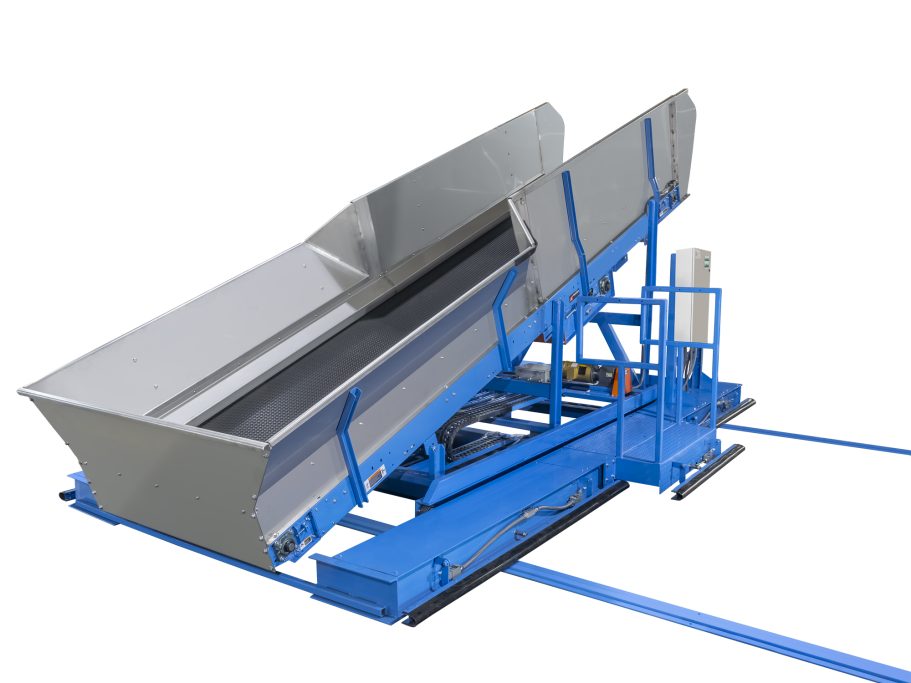

Laundry Transfer Shuttle Cart

This heavy duty cart efficiently transports up to 1000lbs of loose laundry. The 72″ retractable stainless steel cart extends to receive laundry from the washing line, then retracts to move laundry onto the dryer line. Complete with a platform and hand rails, an operator can safely control the shuttle as it moves side to side along the lower track.

ref#663996

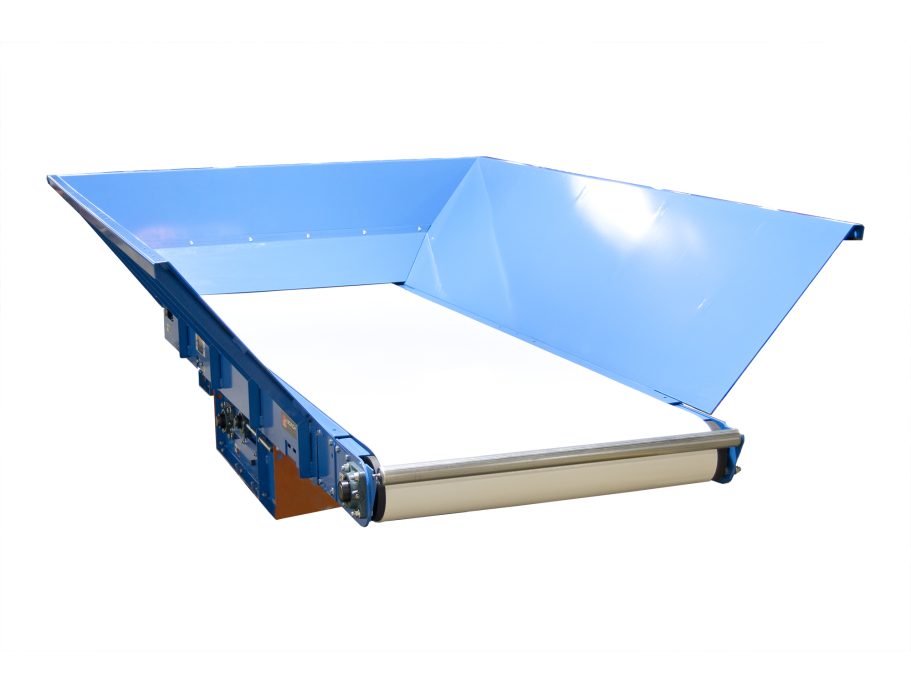

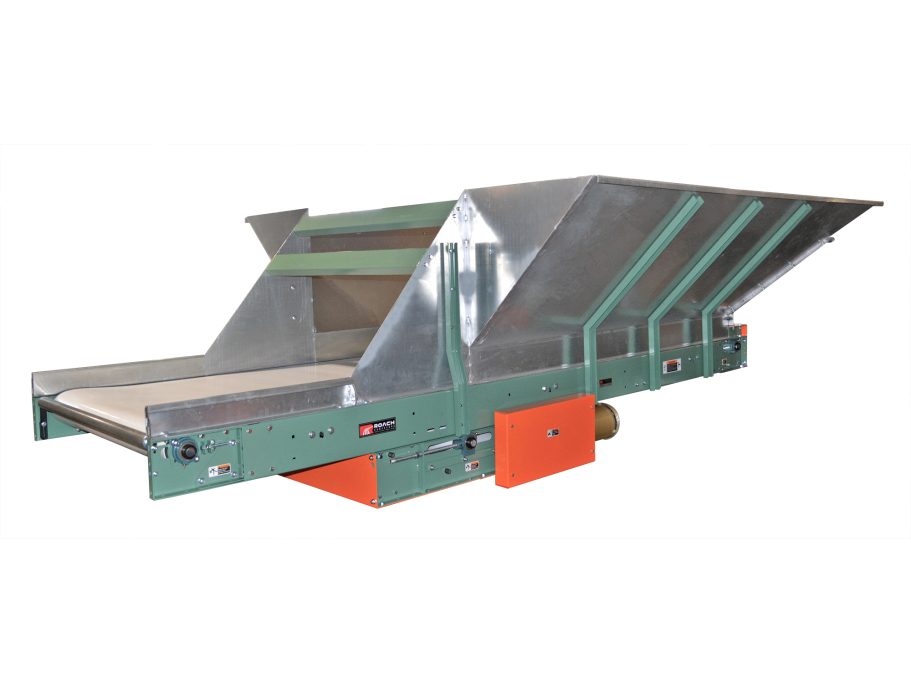

700SB | Laundry Receiving Crescent Belt

Loose laundry loads weighing 400lbs infeed into an 8′ long 36″ high hopper. Attached knock-down bars insure laundry gets on the belt while belt guards and deflectors prevent laundry from tangling in the belt. Raised crescent nodules on the belt provide grip to move laundry up an incline.

ref#548239, 548112

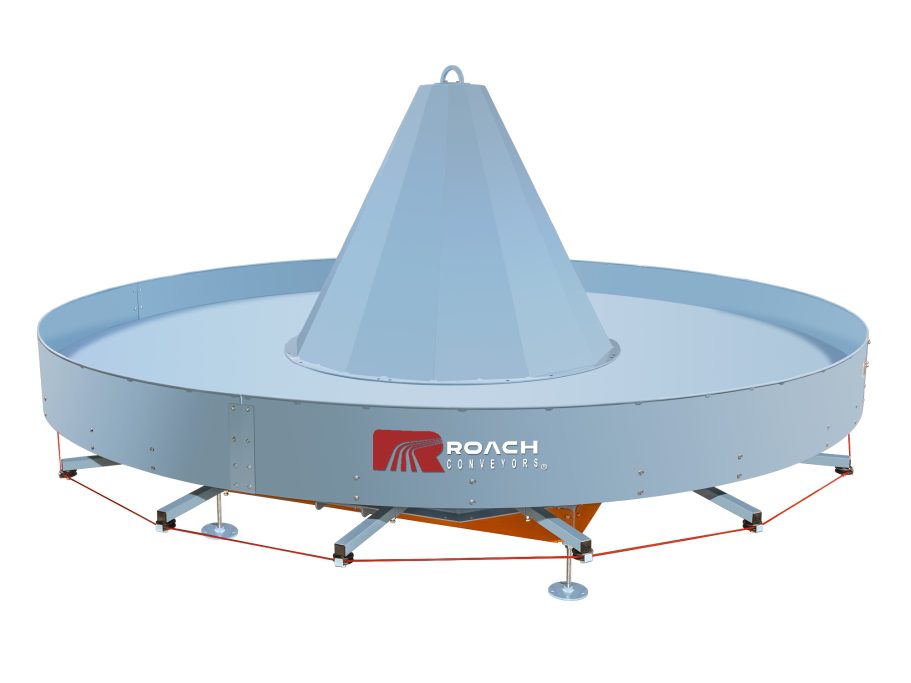

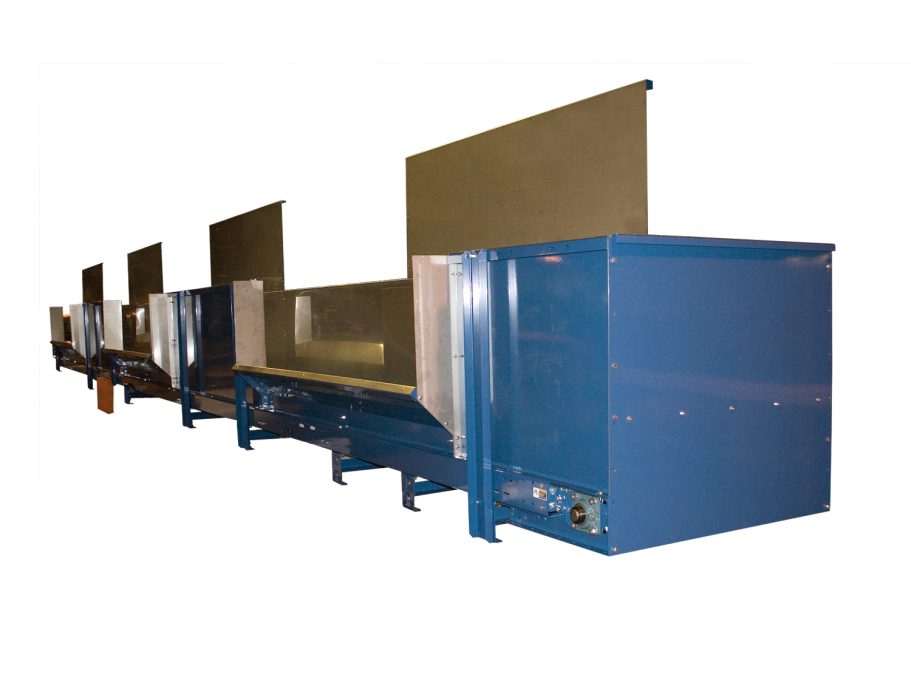

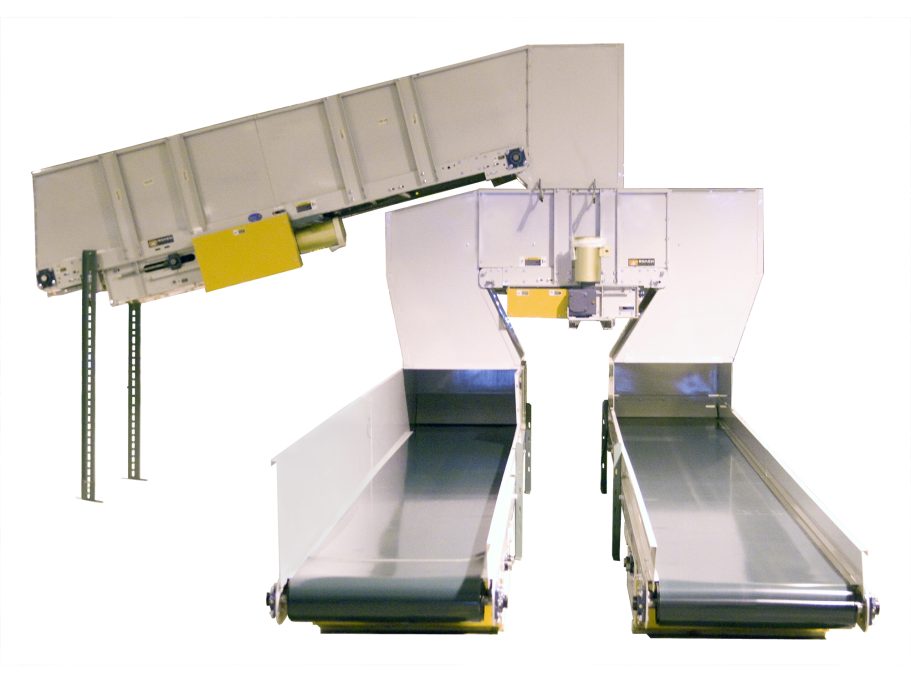

Laundry Level Selector w/ Transfer Carts

Dual lane level selector receives dry folded laundry bundles and inclines or declines to one of three levels. Laundry is transferred onto a transfer cart at each level. Transfer carts’ guard rails prevent laundry from falling off during lateral movement. The transfer carts transfer the laundry onto one of six receiving conveyor lines.

ref#498216-498219