GLASS & SOLAR HANDLING

Glass and solar handling conveyors are designed to move fragile, high value panels with controlled contact, precise positioning, and predictable motion. These systems support the handling of raw glass sheets, tempered glass, and finished solar modules where surface protection and dimensional stability are critical. Conveyor designs focus on minimizing contact points, maintaining alignment, and enabling smooth transitions between processing steps such as cutting, washing, coating, inspection, and packing.

Polyurethane banded roller conveyors are commonly used in glass and solar applications due to their minimal points of contact and non marking surface characteristics. By supporting panels on narrow bands rather than full width rollers, these conveyors reduce surface friction while maintaining consistent tracking. Vertical glass accumulation systems allow panels to be staged safely in an upright position, conserving floor space and improving access for downstream equipment. Non marking grid turntables and specialized transfers enable controlled changes in direction while maintaining panel orientation and spacing.

Glass and solar handling conveyors are engineered as integrated systems rather than standalone components. Transfers, turntables, and accumulation zones are designed to work together, allowing panels to move through complex layouts without manual intervention. These systems are commonly customized to accommodate panel size, weight, edge condition, and process flow requirements while maintaining repeatable motion across the line.

Applications

- Glass cutting and edging lines

- Solar panel assembly and lamination

- Washing, coating, and tempering processes

- Inspection and quality control stations

- Packing and palletizing operations

- Infeed and discharge between automated machines

Industries

- Architectural glass manufacturing

- Solar energy and photovoltaic production

- Automotive glass processing

- Building materials manufacturing

- Specialty glass fabrication

- Renewable energy equipment manufacturing

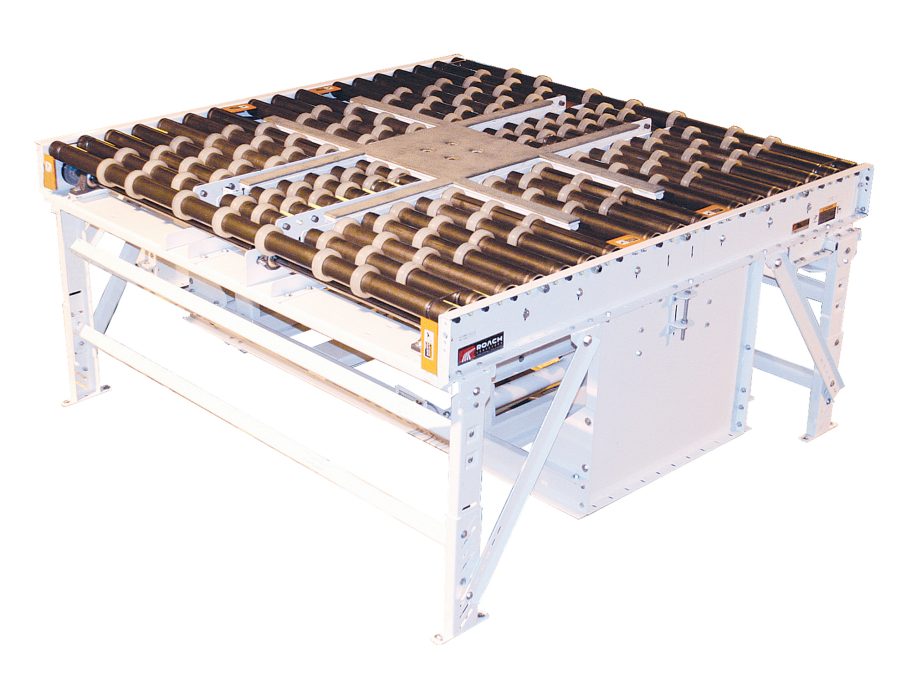

Glass Handling Accumulator | Inspection Station

Vertically adjustable accumulation station designed to store glass panels in an upright stack. Rollers fitted with polyurethane bands limit contact points on the panels, reducing the risk of surface damage or breakage. An integrated safety caged inspection station raises panels vertically to support full visual access during inspection. Polyurethane banded rollers maintain controlled support while protecting glass surfaces throughout the inspection process.

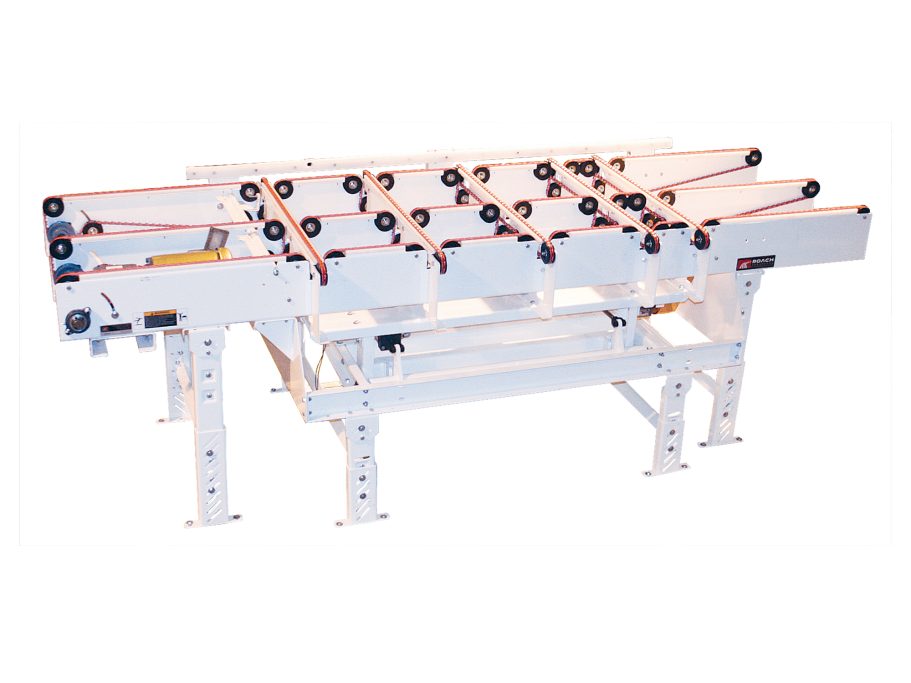

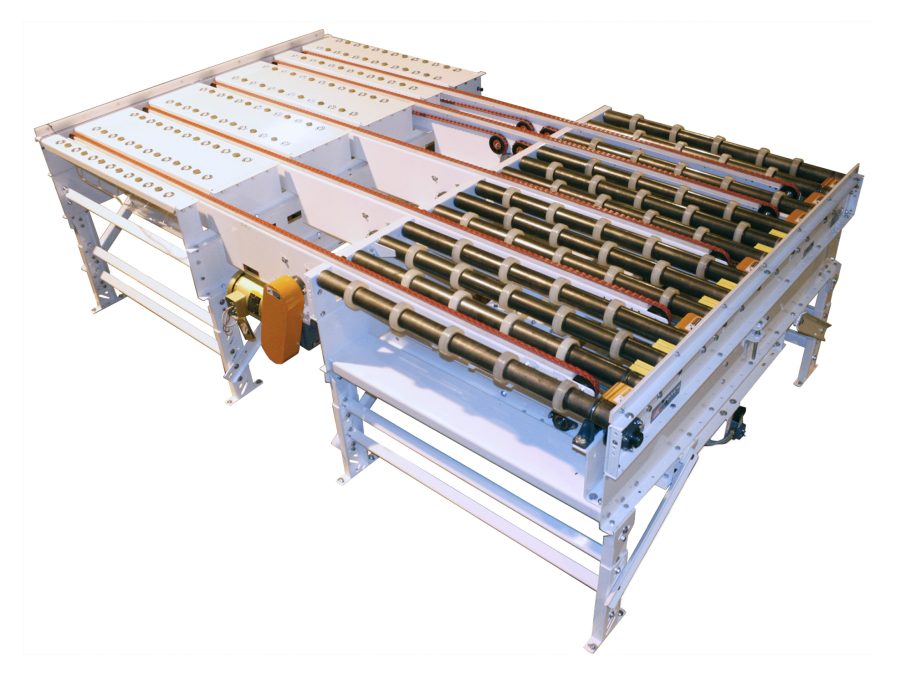

Glass Handling Inspection Station w/ Reject Transfer

Polyurethane bands are located on rollers to provide minimal points of contact on the glass panels and reduce the chance of breakage or scarring. Non-marking Powertwist belt can be used to transfer the glass panels to and from the inspection table and the conveying line.

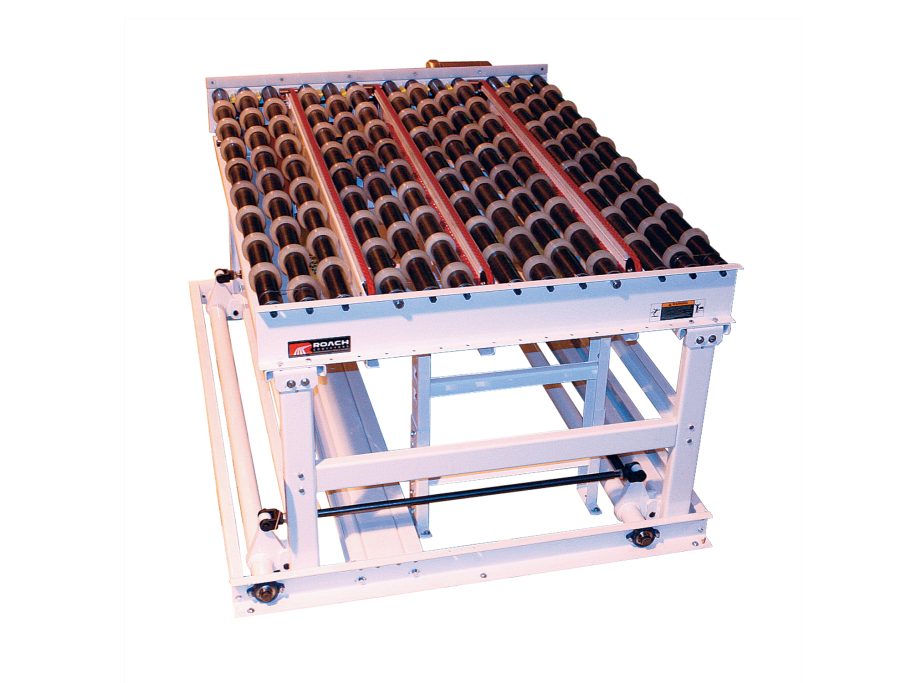

Solar Handling Vertical Accumulator

Polyurethane bands are located on rollers to provide minimal points of contact on the solar panels and reduce the chance of breakage or scarring. Power Twist belts provide 90° transfers that reduce vibrations and potential damage to the solar panels. The panels accumulate in a stacked position.