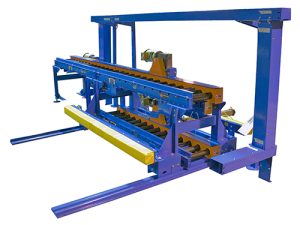

Heavy-Duty Pallet De-Stacker Conveyor

Designed for high-throughput pallet handling in demanding industrial environments, this Heavy-Duty Pallet De-Stacker provides reliable, automated pallet separation with minimal operator intervention. Engineered for durability and precision, it streamlines pallet flow while maintaining consistent alignment and spacing.

High-Capacity Pallet Staging

The infeed section accommodates up to 15 pallets stacked and loaded from the rear of the conveyor. Integrated forklift alignment guides ensure accurate positioning during loading, reducing handling time and minimizing the risk of misalignment or damage.

Controlled, Single Pallet Dispensing

Pallets are discharged individually at a controlled rate of 35 feet per minute, providing a steady, predictable flow to downstream operations. This controlled release is ideal for automated lines requiring consistent pallet spacing.

Robust De-Stacking Mechanism

At the dispensing stage, a pneumatic lift table raises through a heavy-duty dual-chain drag conveyor. As the table lifts, pneumatic clamps secure the second pallet from the bottom, stabilizing the remaining stack. The lift table then lowers, allowing the bottom pallet to dispense forward while the rest of the stack remains securely supported.

Precise Pallet Discharge

Once released, the pallet travels along a heavy-duty two-chain drag conveyor and exits through pallet discharge alignment guides, ensuring proper orientation for downstream systems.

Built for Industrial Reliability

Constructed with heavy-duty components and proven pneumatic controls, this pallet de-stacker is ideal for manufacturing, warehousing, and distribution environments where uptime, safety, and consistency are critical.

Key Benefits:

Holds up to 15 pallets per cycle

Forklift-friendly rear loading with alignment guides

Smooth, controlled single-pallet dispensing

Heavy-duty dual-chain drag conveyor construction

Reliable pneumatic lift and clamping system

Consistent pallet alignment at discharge

This heavy-duty pallet de-stacker delivers dependable performance, reduces manual handling, and integrates seamlessly into automated material handling systems.