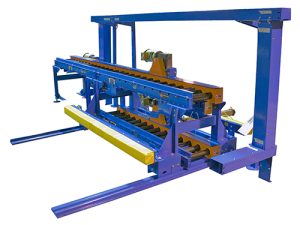

The Roach Conveyors MCS Modular Connect System is designed for high-volume environments where layout flexibility and dependability are essential. With plug-and-play electrical components, the quick deploy modular design allows individual segments to be easily assembled, extended, or reconfigured to meet evolving workflow demands. The MCS minimizes on-site installation time with pre-wired easy connect conveyors, reducing the need for additional cabling in the field.

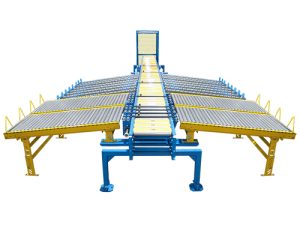

Driven by a 1/14hp 130vdc motor, the Roach MC System runs up to 150 ft/m & handles 50lbs/ft. The 1.9” band driven rollers enable smooth continuous movement through curved sections, side aligning skews, centralizing herringbones, coated roller inclines and more. Heavy-duty 6” casters with brake and swivel locks enable smooth movement to easily adjust to evolving business demands.

With optional accumulation features, the MCS transports packages & polybags through light bar monitored accumulation zones allowing full control of sorting, packaging, quality checks, & load balancing. Increase operation safety with optional features such as emergency stop buttons, guard rails, and sensors.

The simple & low maintenance Modular Connect System is one of the most efficient transportation solutions available for most package handling applications including parcel, e-commerce, warehouses, distribution centers, manufacturing & more.

ACCESSORIES/OPTIONS

Guard Rails

Coated Rollers

Lightbar Accumulation

E-Stops

ABEC Sealed Precision Bearings

MODULE TYPES

Straights

Curves

Centralizing Herringbones

Side Pushing Skews

Coated Roller Inclines