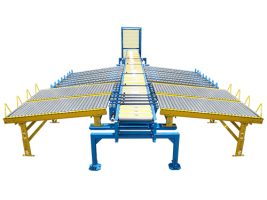

Model 796RBF floor-to-floor conveyor provides higher load capacity, reversible flow and nose-over allows for simple adjustments for inclines 0-35°. Shown with optional supports, knee braces, chain driven feeder and right hand drive. All units furnished standard with left hand drive.

796RBF | Roller Bed Belt Conveyor Incline

| Specifications | BELTING: Black PVC rough-top. DRIVE PULLEY: 8″ dia. with 1-7/16″ dia. shaft, both crowned and fully lagged. CARRIER ROLLERS: 1.9″ dia. x 16 ga. steel rollers, model 196S. TAIL PULLEY: 4″ dia., crowned, with 1-3/16″ dia. shaft. CENTER DRIVE: Reversible drive with 24″ belt take-up. NOSE-OVER: Provides smooth transition from incline to horizontal position. Single nose-over adjust 0-20 degrees; double nose-over adjust 0-35 degrees. BEARINGS: All pulley bearings are precision, heavy duty, lubricated, ball bearing units with cast iron housings. RETURN ROLLERS: 1.9″ dia. x 16 ga. steel, model 196S, adjustable. BELT SPEED: 60 FPM, constant. BED: 7″ x 12 ga. channel frame. FLOOR SUPPORTS: Optional MOTOR DRIVE: 1/3 HP, 230/460/3, 60 cycle, ODP right angle gear motor. ROLLER CHAIN: Drive pulley is driven by No. 50 roller chain for 1-1/2 HP or less and No. 60 chain on larger drives. Chain take-up provided on motor base. ELECTRICAL CONTROLS: Optional |

|---|

796RBF

Model 796RBF floor-to-floor conveyor provides higher load capacity, reversible flow and nose-over allows for simple adjustments for inclines 0-35°. Shown with optional supports, knee braces, chain driven feeder and right hand drive. All units furnished standard with left hand drive.

| Specifications | BELTING: Black PVC rough-top. DRIVE PULLEY: 8″ dia. with 1-7/16″ dia. shaft, both crowned and fully lagged. CARRIER ROLLERS: 1.9″ dia. x 16 ga. steel rollers, model 196S. TAIL PULLEY: 4″ dia., crowned, with 1-3/16″ dia. shaft. CENTER DRIVE: Reversible drive with 24″ belt take-up. NOSE-OVER: Provides smooth transition from incline to horizontal position. Single nose-over adjust 0-20 degrees; double nose-over adjust 0-35 degrees. BEARINGS: All pulley bearings are precision, heavy duty, lubricated, ball bearing units with cast iron housings. RETURN ROLLERS: 1.9″ dia. x 16 ga. steel, model 196S, adjustable. BELT SPEED: 60 FPM, constant. BED: 7″ x 12 ga. channel frame. FLOOR SUPPORTS: Optional MOTOR DRIVE: 1/3 HP, 230/460/3, 60 cycle, ODP right angle gear motor. ROLLER CHAIN: Drive pulley is driven by No. 50 roller chain for 1-1/2 HP or less and No. 60 chain on larger drives. Chain take-up provided on motor base. ELECTRICAL CONTROLS: Optional |

|---|

796RBF

Accumulation Conveyors(9)

Accumulation

Belt Conveyors(10)

Belt Conveyors

Belt Driven Live Roller(7)

Belt Driven Live Roller

Chain Drag(5)

Chain Driven Live Roller(11)

Chain Driven Live Roller

Flexible Conveyors(2)

Flexible Conveyors

Gravity Conveyors(19)

Gravity Conveyors

Line Shaft(9)

Line Shaft

MDZ | Motor Driven Zone Accumulator(2)

MDZ | Motor Driven Zone Accumulator

Parts Conveyor(3)

Parts Conveyor

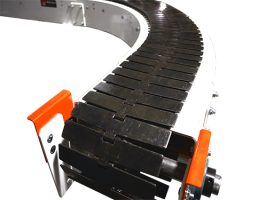

Plastic Belt(9)

Plastic Belt

Powered Roller(13)

Powered Roller

Singulation(1)

Singulation

Slat Conveyors(2)

Slat Conveyors

Transfers(8)

Transfers

Wire Mesh Belt(4)

Wire Mesh Belt

Barrel Conveyors(3)

Barrel Conveyors

Glass & Solar Handling(8)

Glass & Solar Handling

Heavy Duty Conveyors(16)

Heavy Duty Conveyors

Laundry(11)

laundry

Lumber & Door(5)

Lumber

MDR | Motor Driven Roller Smart Conveyors(6)

MDR | Motor Driven Roller Smart Conveyors

Sortation Conveyors(7)

Sortation Conveyors

Special Transfers(11)

Special Transfers

Stackers | Destackers(2)

Stackers/Destackers

Stops | Barriers | Walkovers(10)

Stops | Barriers | Walkovers

Tabletop Chain Conveyors(5)

Tabletop Chain Conveyors

Transfer Carts(9)

Transfer Carts

Turntables(17)

Turntables

Upenders | Downenders | Rollovers(10)

Upenders | Downenders | Rollovers

Vertical Conveyors(8)

Vertical Conveyors

Wheel & Tire Conveyors(4)

Wheel & Tire Conveyors