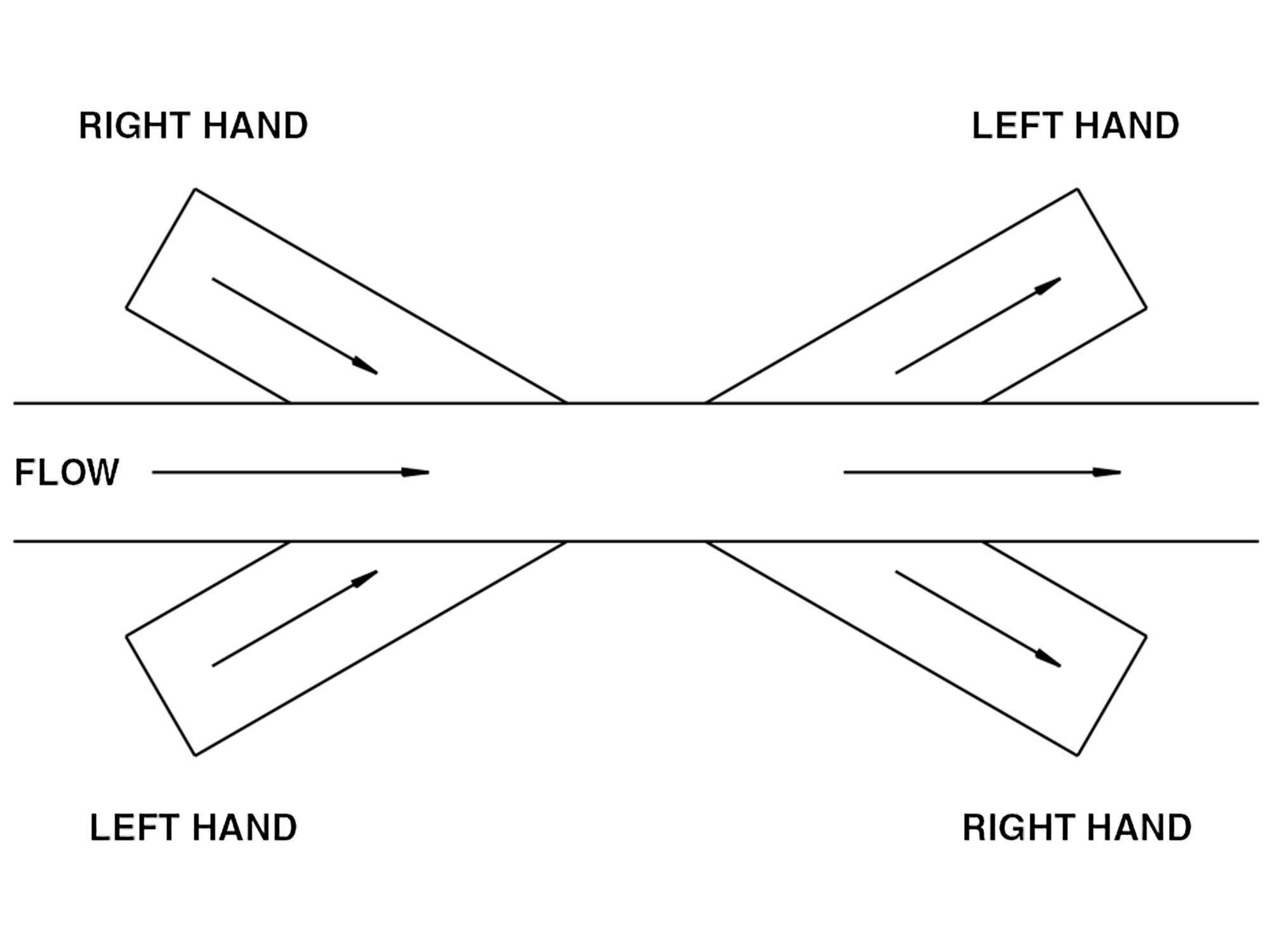

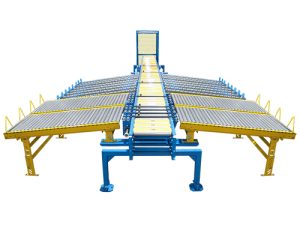

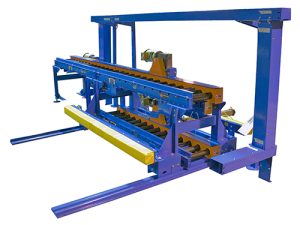

Line shaft converging spur modules, model 796LSS, allow product to flow from spur lines and merge onto straight line shaft driven conveyor. Spur modules are designed to be driven by 796LS, thus decreasing overall number of drives in the conveyor system.