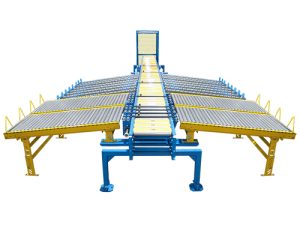

Model 738LSC features tapered rollers to help product maintain orientation. NO drive is required since it is designed to be driven from 738LS straight line shaft driven sections and includes close roller centers as a standard feature.

Model 738LSC features tapered rollers to help product maintain orientation. NO drive is required since it is designed to be driven from 738LS straight line shaft driven sections and includes close roller centers as a standard feature.

| Specifications | TREAD ROLLERS: 1.9″ dia. to 1-3/8" 16 ga. tapered steel, model 138T w/ 5/16″ hex, grooved. DRIVE BELT: 1/8″ dia. polyurethane belts; nominal 7.5 lbs. per roller drive. DRIVE SHAFT: 1″ dia. C1018 cold rolled steel shaft. COUPLINGS: Located on both or one end. UNIVERSAL JOINTS: 4 per 90° and 60° curve; 2 per 45° and 30° curve. TANGENTS: 1’-0” both ends on 60° and 90°; 1’-6” both ends on 30° and 45°. 1’-0” infeed, 1’-0” discharge and no center tangent on 180°; SIDE CHANNEL: 7” x 1-1/2” x 12 ga. formed steel channel frame. FLOOR SUPPORTS: Optional |

|---|

738LSC

Model 738LSC features tapered rollers to help product maintain orientation. NO drive is required since it is designed to be driven from 738LS straight line shaft driven sections and includes close roller centers as a standard feature.

| Specifications | TREAD ROLLERS: 1.9″ dia. to 1-3/8" 16 ga. tapered steel, model 138T w/ 5/16″ hex, grooved. DRIVE BELT: 1/8″ dia. polyurethane belts; nominal 7.5 lbs. per roller drive. DRIVE SHAFT: 1″ dia. C1018 cold rolled steel shaft. COUPLINGS: Located on both or one end. UNIVERSAL JOINTS: 4 per 90° and 60° curve; 2 per 45° and 30° curve. TANGENTS: 1’-0” both ends on 60° and 90°; 1’-6” both ends on 30° and 45°. 1’-0” infeed, 1’-0” discharge and no center tangent on 180°; SIDE CHANNEL: 7” x 1-1/2” x 12 ga. formed steel channel frame. FLOOR SUPPORTS: Optional |

|---|

738LSC