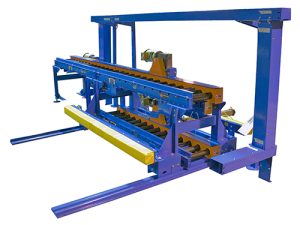

725TB trough bed belt conveyor is ideal for handling chips, slugs, scrap wood, paper waste, boxes, packages and cartons. The troughed frame design offers integral guard rails for many trash conveyor applications.

725TB trough bed belt conveyor is ideal for handling chips, slugs, scrap wood, paper waste, boxes, packages and cartons. The troughed frame design offers integral guard rails for many trash conveyor applications.

| Specifications | BELTING: PVC-120 black. DRIVE PULLEY: 4″ dia. with 1-3/16″ dia. shaft or 8″ dia. with 1-7/16″ dia. shaft, both crowned and fully lagged. TAIL PULLEY: 4″ dia., crowned, with 1-3/16″ dia. shaft. END DRIVE: Allows one-direction (unit) operation; add optional center drive for reversible application. TAKE-UP: Screw type unit at tail pulley provides 12″ belt take-up. BEARINGS: All pulley bearings are precision, heavy duty, lubricated, ball bearing units with cast iron housings. RETURN ROLLERS: 1.9″ dia. x 16 ga. steel, model 196S, adjustable. BELT SPEED: 60 FPM, constant. BED: 7″ deep x 12 ga. box type bed with bed pan braces (all widths) and with 2-1/2″ deep x 12 ga. formed trough with formed flanges on sides to provide extra strength. FLOOR SUPPORTS: Optional MOTOR DRIVE: 1/3 HP, 230/460/3, 60 cycle, ODP right angle gear motor. ROLLER CHAIN: Drive pulley is driven by No. 50 roller chain for 1-1/2 HP or less and No. 60 chain on larger drives. Chain take-up provided on motor base. SAFETY POP-OUT ROLLERS: Standard on both ends, 1.9″ dia x 16 ga. steel roller, model 196S. ELECTRICAL CONTROLS: Optional |

|---|

725TB

725TB trough bed belt conveyor is ideal for handling chips, slugs, scrap wood, paper waste, boxes, packages and cartons. The troughed frame design offers integral guard rails for many trash conveyor applications.

| Specifications | BELTING: PVC-120 black. DRIVE PULLEY: 4″ dia. with 1-3/16″ dia. shaft or 8″ dia. with 1-7/16″ dia. shaft, both crowned and fully lagged. TAIL PULLEY: 4″ dia., crowned, with 1-3/16″ dia. shaft. END DRIVE: Allows one-direction (unit) operation; add optional center drive for reversible application. TAKE-UP: Screw type unit at tail pulley provides 12″ belt take-up. BEARINGS: All pulley bearings are precision, heavy duty, lubricated, ball bearing units with cast iron housings. RETURN ROLLERS: 1.9″ dia. x 16 ga. steel, model 196S, adjustable. BELT SPEED: 60 FPM, constant. BED: 7″ deep x 12 ga. box type bed with bed pan braces (all widths) and with 2-1/2″ deep x 12 ga. formed trough with formed flanges on sides to provide extra strength. FLOOR SUPPORTS: Optional MOTOR DRIVE: 1/3 HP, 230/460/3, 60 cycle, ODP right angle gear motor. ROLLER CHAIN: Drive pulley is driven by No. 50 roller chain for 1-1/2 HP or less and No. 60 chain on larger drives. Chain take-up provided on motor base. SAFETY POP-OUT ROLLERS: Standard on both ends, 1.9″ dia x 16 ga. steel roller, model 196S. ELECTRICAL CONTROLS: Optional |

|---|

725TB