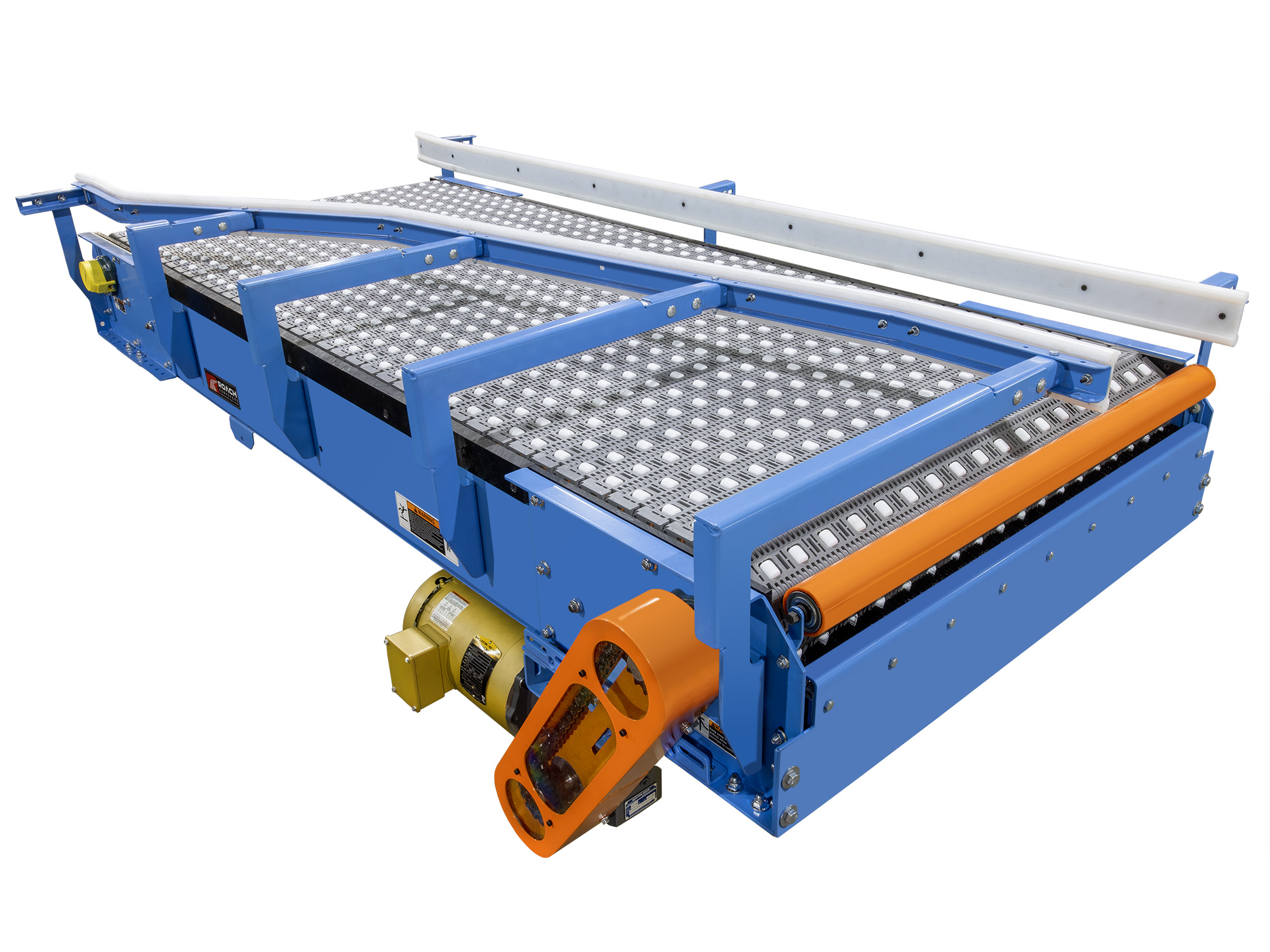

BELTING: Series 400 transverse roller top gray polypropylene belt with acetal rollers and stainless steel roller axles, FDA approved belting.

DRIVE SPROCKETS: 7.8″ pitch dia. with 1.5″ square bore. Available with OPTIONAL 10.1″ pitch dia. sprockets with 1.5″ or 2.5″ square bore.

TAIL SPROCKETS: 7.8″ pitch dia. with 1.5″ square bore. Available with OPTIONAL 10.1″ pitch dia. sprockets with 1.5″ or 2.5″ square bore.

END DRIVE: Allows one-direction (unit) operation.

BEARINGS: Drive and tail shaft bearings are precision, heavy duty, lubricated, ball bearing units with cast iron housings.

BED: 7″ x 1-1/2″ x 10 ga. channel frame with open style bed construction and UHMW wearstrips mounted to longitudinal channels.

TAKE-UP: Catenary type located at discharge end.

RETURN ROLLERS: 1.9″ dia. x 16 ga. steel, model 196S, adjustable with rubber sleeves.

BELT SPEED: 60 FPM, constant.

FLOOR SUPPORT: Optional.

MOTOR DRIVE: 1/3 HP, 230/460/3, 60 cycle, ODP right angle gear motor.

ROLLER CHAIN: Drive shaft is driven by No. 50 roller chain for 1-1/2 HP or less and No. 60 chain on larger drives. Chain take-up provided on motor base.

ELECTRICAL CONTROLS: Optional

|