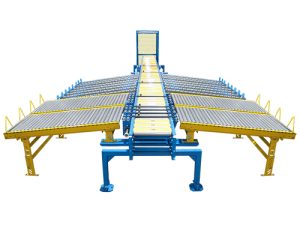

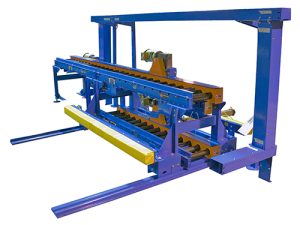

Conveyors with raised rib plastic belting are designed for transporting, accumulating and transferring cans, bottles or other small items that are normally difficult to transfer. Belt tracking problems are eliminated with model 700RR.

Conveyors with raised rib plastic belting are designed for transporting, accumulating and transferring cans, bottles or other small items that are normally difficult to transfer. Belt tracking problems are eliminated with model 700RR.

| Specifications | BELTING: Series 400 raised rib gray polypropylene belt, FDA approved belt. Finger transfer plates provided both ends of conveyor to facilitate smooth product transfer. DRIVE SPROCKETS: 7.8″ pitch dia. with 1.5″ square bore. Available with OPTIONAL 10.1″ pitch dia. sprockets with 1.5″ or 2.5″ square bore. TAIL SPROCKETS: 7.8″ pitch dia. with 1.5″ square bore. Available with OPTIONAL 10.1″ pitch dia. sprockets with 1.5″ or 2.5″ square bore. END DRIVE: Allows one-direction (unit) operation. BEARINGS: Drive and tail shaft bearings are precision, heavy duty, lubricated, ball bearing units with cast iron housings. BED: 7″ x 1-1/2″ x 10 ga. channel frame with open style bed construction and UHMW wearstrips mounted to longitudinal channels. TAKE-UP: Catenary type located at discharge end. RETURN ROLLERS: 1.9″ dia. x 16 ga. steel, model 196S, adjustable with rubber sleeves. BELT SPEED: 60 FPM, constant. FLOOR SUPPORTS: Optional. MOTOR DRIVE: 1/3 HP, 230/460/3, 60 cycle, ODP right angle gear motor. ROLLER CHAIN: Drive shaft is driven by No. 50 roller chain for 1-1/2 HP or less and No. 60 chain on larger drives. Chain take-up provided on motor base. ELECTRICAL CONTROLS: Optional |

|---|

700RR

Conveyors with raised rib plastic belting are designed for transporting, accumulating and transferring cans, bottles or other small items that are normally difficult to transfer. Belt tracking problems are eliminated with model 700RR.

| Specifications | BELTING: Series 400 raised rib gray polypropylene belt, FDA approved belt. Finger transfer plates provided both ends of conveyor to facilitate smooth product transfer. DRIVE SPROCKETS: 7.8″ pitch dia. with 1.5″ square bore. Available with OPTIONAL 10.1″ pitch dia. sprockets with 1.5″ or 2.5″ square bore. TAIL SPROCKETS: 7.8″ pitch dia. with 1.5″ square bore. Available with OPTIONAL 10.1″ pitch dia. sprockets with 1.5″ or 2.5″ square bore. END DRIVE: Allows one-direction (unit) operation. BEARINGS: Drive and tail shaft bearings are precision, heavy duty, lubricated, ball bearing units with cast iron housings. BED: 7″ x 1-1/2″ x 10 ga. channel frame with open style bed construction and UHMW wearstrips mounted to longitudinal channels. TAKE-UP: Catenary type located at discharge end. RETURN ROLLERS: 1.9″ dia. x 16 ga. steel, model 196S, adjustable with rubber sleeves. BELT SPEED: 60 FPM, constant. FLOOR SUPPORTS: Optional. MOTOR DRIVE: 1/3 HP, 230/460/3, 60 cycle, ODP right angle gear motor. ROLLER CHAIN: Drive shaft is driven by No. 50 roller chain for 1-1/2 HP or less and No. 60 chain on larger drives. Chain take-up provided on motor base. ELECTRICAL CONTROLS: Optional |

|---|

700RR