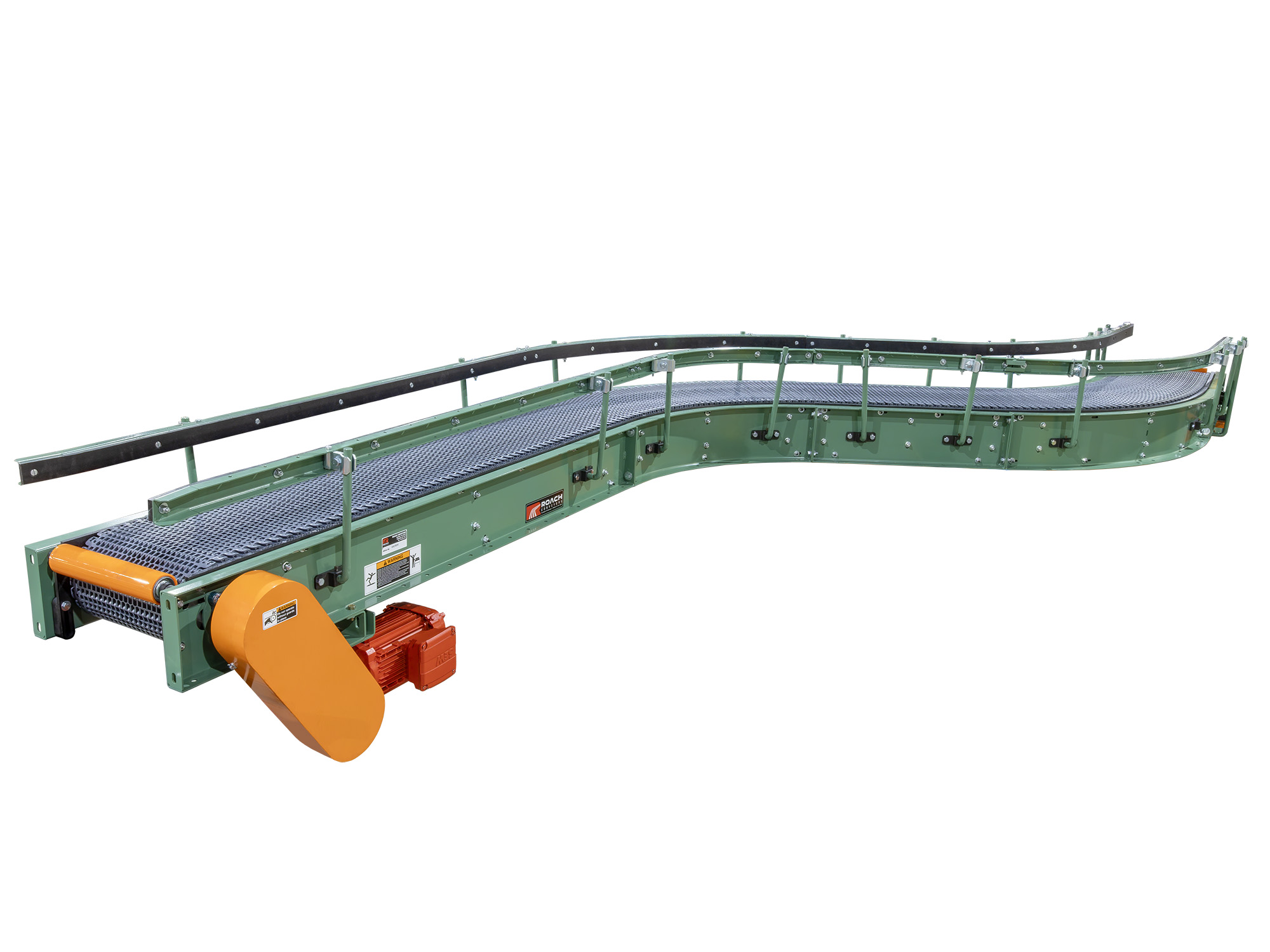

BELTING: Series 2200 flush grid gray curved polypropylene belt, FDA & USDA approved belting.

DRIVE SPROCKETS: 5.3″ pitch dia. with 1.5″ square bore. Available with OPTIONAL 6.3″ or 7.7″ pitch dia. sprockets with 1.5″ or 2.5″ square bore.

TAIL SPROCKETS: 5.3″ pitch dia. with 1.5″ square bore. Available with OPTIONAL 6.3″ or 7.7″ pitch dia. sprockets with 1.5″ or 2.5″ square bore.

END DRIVE: Allows one-direction operation ONLY; this conveyor is NOT reversible.

BEARINGS: End shafts are supported by precision, heavy duty, lubricated, ball bearing units with cast iron housings.

BED: 7″ x 1-1/2″ x 10 ga. formed steel channel frame with UHWW wearstrips attached to bed and belt return pan.

TAKE-UP: Catenary type located at discharge end.

MINIMUM RADIUS: 2.2 x belt width, measured from inside edge of belt.

TANGENTS: Minimum length is 1.5 x belt width located at each end of conveyor; minimum of 3′ at discharge end required with 5′ recommended. Optional additional tangent may be located at discharge end.

BELT SPEED: 60 FPM, constant.

FLOOR SUPPORT: Optional.

DIRECTION OF FLOW: Specify right hand or left hand.

MOTOR DRIVE: 1/3 HP, 230/460/3, 60 cycle, ODP right angle gear motor on 45 degree and 90 degree curves; 3/4 HP supplied on all 180 degree curves.

ROLLER CHAIN: Drive shaft is driven by No. 50 chain.

ELECTRICAL CONTROLS: Optional

|