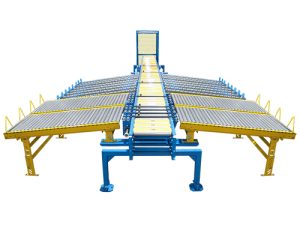

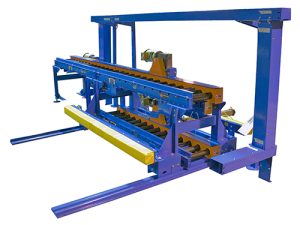

Model 700FFT is the choice for floor-to-floor, inclined or declined carton handling applications. Eliminate belt tracking problems with plastic belt on model 700FFT. Unit shown with optional supports and knee braces.

Model 700FFT is the choice for floor-to-floor, inclined or declined carton handling applications. Eliminate belt tracking problems with plastic belt on model 700FFT. Unit shown with optional supports and knee braces.

| Specifications | BELTING: Series 900 flat friction top gray polypropylene belt with black rubber top modules. DRIVE SPROCKETS: 6.1″ pitch dia. with 1.5″ square bore. Available with OPTIONAL 6.1″ pitch dia. with 2.5″ square bore and 6.8″ pitch dia. sprockets with 1.5″ or 2.5″ square bore. TAIL SPROCKETS: 6.1″ pitch dia. with 1.5″ square bore. Available with OPTIONAL 6.1″ pitch dia. with 2.5″ square bore and 6.8″ pitch dia. sprockets with 1.5″ or 2.5″ square bore. END DRIVE: Allows one-direction (unit) operation. BEARINGS: Drive and tail shaft bearings are precision, heavy duty, lubricated, ball bearing units with cast iron housings. BED: 7″ x 1-1/2″ x 10 ga. channel frame with open style bed construction and UHMW wearstrips mounted to longitudinal channels. TAKE-UP: Catenary type located at discharge end. RETURN ROLLERS: 1.9″ dia. x 16 ga. steel, model 196S, adjustable with rubber sleeves. BELT SPEED: 60 FPM, constant. FLOOR SUPPORTS: Optional. MOTOR DRIVE: 1/3 HP, 230/460/3, 60 cycle, ODP right angle gear motor. ROLLER CHAIN: Drive shaft is driven by No. 50 roller chain for 1-1/2 HP or less and No. 60 chain on larger drives. Chain take-up provided on motor base. ELECTRICAL CONTROLS: Optional |

|---|

700FFT

Model 700FFT is the choice for floor-to-floor, inclined or declined carton handling applications. Eliminate belt tracking problems with plastic belt on model 700FFT. Unit shown with optional supports and knee braces.

| Specifications | BELTING: Series 900 flat friction top gray polypropylene belt with black rubber top modules. DRIVE SPROCKETS: 6.1″ pitch dia. with 1.5″ square bore. Available with OPTIONAL 6.1″ pitch dia. with 2.5″ square bore and 6.8″ pitch dia. sprockets with 1.5″ or 2.5″ square bore. TAIL SPROCKETS: 6.1″ pitch dia. with 1.5″ square bore. Available with OPTIONAL 6.1″ pitch dia. with 2.5″ square bore and 6.8″ pitch dia. sprockets with 1.5″ or 2.5″ square bore. END DRIVE: Allows one-direction (unit) operation. BEARINGS: Drive and tail shaft bearings are precision, heavy duty, lubricated, ball bearing units with cast iron housings. BED: 7″ x 1-1/2″ x 10 ga. channel frame with open style bed construction and UHMW wearstrips mounted to longitudinal channels. TAKE-UP: Catenary type located at discharge end. RETURN ROLLERS: 1.9″ dia. x 16 ga. steel, model 196S, adjustable with rubber sleeves. BELT SPEED: 60 FPM, constant. FLOOR SUPPORTS: Optional. MOTOR DRIVE: 1/3 HP, 230/460/3, 60 cycle, ODP right angle gear motor. ROLLER CHAIN: Drive shaft is driven by No. 50 roller chain for 1-1/2 HP or less and No. 60 chain on larger drives. Chain take-up provided on motor base. ELECTRICAL CONTROLS: Optional |

|---|

700FFT