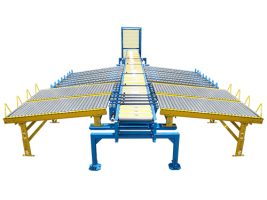

Slider bed belt conveyors remain the most popular of all powered conveyors, providing an economical means of transporting goods for packing, testing, inspecting and various assembly line operations.

700SB | Slider Bed Medium Duty Belt Conveyor

| Specifications | BELTING: PVC-120 black. DRIVE PULLEY: 4″ dia. with 1-3/16″ dia. shaft or 8″ dia. with 1-7/16″ dia. shaft, both crowned and fully lagged. TAIL PULLEY: 4″ dia., crowned, with 1-3/16″ dia. shaft. END DRIVE: Allows one-direction (unit) operation; add optional center drive for reversible application. TAKE-UP: Screw type unit at tail pulley provides 12″ belt take-up. BEARINGS: All pulley bearings are precision, heavy duty, lubricated, ball bearing units with cast iron housings. RETURN ROLLERS: 1.9″ dia. x 16 ga. steel, model 196S, adjustable. BELT SPEED: 60 FPM, constant. BED: 7″ x 12 ga. channel frame with 14 ga. slider bed 9″-27″ BF; 12 ga. bed 33″ BF and above with bed pan braces. FLOOR SUPPORTS: Optional MOTOR DRIVE: 1/3 HP, 230/460/3, 60 cycle, ODP right angle gear motor. ROLLER CHAIN: Drive pulley is driven by No. 50 roller chain for 1-1/2 HP or less and No. 60 chain on larger drives. Chain take-up provided on motor base. SAFETY POP-OUT ROLLERS: Standard on both ends, 1.9″ dia x 16 ga. steel roller, model 196S. ELECTRICAL CONTROLS: Optional |

|---|

700SB

Slider bed belt conveyors remain the most popular of all powered conveyors, providing an economical means of transporting goods for packing, testing, inspecting and various assembly line operations.

| Specifications | BELTING: PVC-120 black. DRIVE PULLEY: 4″ dia. with 1-3/16″ dia. shaft or 8″ dia. with 1-7/16″ dia. shaft, both crowned and fully lagged. TAIL PULLEY: 4″ dia., crowned, with 1-3/16″ dia. shaft. END DRIVE: Allows one-direction (unit) operation; add optional center drive for reversible application. TAKE-UP: Screw type unit at tail pulley provides 12″ belt take-up. BEARINGS: All pulley bearings are precision, heavy duty, lubricated, ball bearing units with cast iron housings. RETURN ROLLERS: 1.9″ dia. x 16 ga. steel, model 196S, adjustable. BELT SPEED: 60 FPM, constant. BED: 7″ x 12 ga. channel frame with 14 ga. slider bed 9″-27″ BF; 12 ga. bed 33″ BF and above with bed pan braces. FLOOR SUPPORTS: Optional MOTOR DRIVE: 1/3 HP, 230/460/3, 60 cycle, ODP right angle gear motor. ROLLER CHAIN: Drive pulley is driven by No. 50 roller chain for 1-1/2 HP or less and No. 60 chain on larger drives. Chain take-up provided on motor base. SAFETY POP-OUT ROLLERS: Standard on both ends, 1.9″ dia x 16 ga. steel roller, model 196S. ELECTRICAL CONTROLS: Optional |

|---|

700SB

Accumulation Conveyors(9)

Accumulation

Belt Conveyors(10)

Belt Conveyors

Belt Driven Live Roller(7)

Belt Driven Live Roller

Chain Drag(5)

Chain Driven Live Roller(11)

Chain Driven Live Roller

Flexible Conveyors(2)

Flexible Conveyors

Gravity Conveyors(19)

Gravity Conveyors

Line Shaft(9)

Line Shaft

MDZ | Motor Driven Zone Accumulator(2)

MDZ | Motor Driven Zone Accumulator

Parts Conveyor(3)

Parts Conveyor

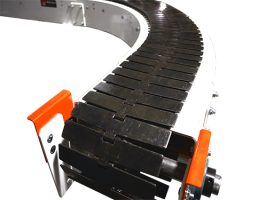

Plastic Belt(9)

Plastic Belt

Powered Roller(13)

Powered Roller

Singulation(1)

Singulation

Slat Conveyors(2)

Slat Conveyors

Transfers(8)

Transfers

Wire Mesh Belt(4)

Wire Mesh Belt

Barrel Conveyors(3)

Barrel Conveyors

Glass & Solar Handling(8)

Glass & Solar Handling

Heavy Duty Conveyors(16)

Heavy Duty Conveyors

Laundry(11)

laundry

Lumber & Door(5)

Lumber

MDR | Motor Driven Roller Smart Conveyors(6)

MDR | Motor Driven Roller Smart Conveyors

Sortation Conveyors(7)

Sortation Conveyors

Special Transfers(11)

Special Transfers

Stackers | Destackers(2)

Stackers/Destackers

Stops | Barriers | Walkovers(10)

Stops | Barriers | Walkovers

Tabletop Chain Conveyors(5)

Tabletop Chain Conveyors

Transfer Carts(9)

Transfer Carts

Turntables(17)

Turntables

Upenders | Downenders | Rollovers(10)

Upenders | Downenders | Rollovers

Vertical Conveyors(8)

Vertical Conveyors

Wheel & Tire Conveyors(4)

Wheel & Tire Conveyors