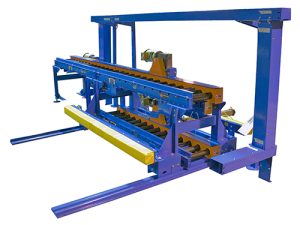

Model 700BSB features a box style slider bed which offers a smooth work surface, ideal for workers stationed beside this conveyor. The 700BSB is an economical choice for tasks such as packing, testing and inspecting.

Model 700BSB features a box style slider bed which offers a smooth work surface, ideal for workers stationed beside this conveyor. The 700BSB is an economical choice for tasks such as packing, testing and inspecting.

| Specifications | BELTING: PVC-120 black. DRIVE PULLEY: 4″ dia. with 1-3/16″ dia. shaft or 8″ dia. with 1-7/16″ dia. shaft, both crowned and fully lagged. TAIL PULLEY: 4″ dia., crowned, with 1-3/16″ dia. shaft. END DRIVE: Allows one-direction (unit) operation; add optional center drive for reversible application. TAKE-UP: Screw type unit at tail pulley provides 12″ belt take-up. BEARINGS: All pulley bearings are precision, heavy duty, lubricated, ball bearing units with cast iron housings. RETURN ROLLERS: 1.9″ dia. x 16 ga. steel, model 196S, adjustable. BELT SPEED: 60 FPM, constant. BED: 7″ x 12 ga. box type construction. FLOOR SUPPORTS: Optional MOTOR DRIVE: 1/3 HP, 230/460/3, 60 cycle, ODP right angle gear motor. ROLLER CHAIN: Drive pulley is driven by No. 50 roller chain for 1-1/2 HP or less and No. 60 chain on larger drives. Chain take-up provided on motor base. SAFETY POP-OUT ROLLERS: Standard on both ends, 1.9″ dia x 16 ga. steel roller, model 196S. ELECTRICAL CONTROLS: Optional |

|---|

700BSB

Model 700BSB features a box style slider bed which offers a smooth work surface, ideal for workers stationed beside this conveyor. The 700BSB is an economical choice for tasks such as packing, testing and inspecting.

| Specifications | BELTING: PVC-120 black. DRIVE PULLEY: 4″ dia. with 1-3/16″ dia. shaft or 8″ dia. with 1-7/16″ dia. shaft, both crowned and fully lagged. TAIL PULLEY: 4″ dia., crowned, with 1-3/16″ dia. shaft. END DRIVE: Allows one-direction (unit) operation; add optional center drive for reversible application. TAKE-UP: Screw type unit at tail pulley provides 12″ belt take-up. BEARINGS: All pulley bearings are precision, heavy duty, lubricated, ball bearing units with cast iron housings. RETURN ROLLERS: 1.9″ dia. x 16 ga. steel, model 196S, adjustable. BELT SPEED: 60 FPM, constant. BED: 7″ x 12 ga. box type construction. FLOOR SUPPORTS: Optional MOTOR DRIVE: 1/3 HP, 230/460/3, 60 cycle, ODP right angle gear motor. ROLLER CHAIN: Drive pulley is driven by No. 50 roller chain for 1-1/2 HP or less and No. 60 chain on larger drives. Chain take-up provided on motor base. SAFETY POP-OUT ROLLERS: Standard on both ends, 1.9″ dia x 16 ga. steel roller, model 196S. ELECTRICAL CONTROLS: Optional |

|---|

700BSB