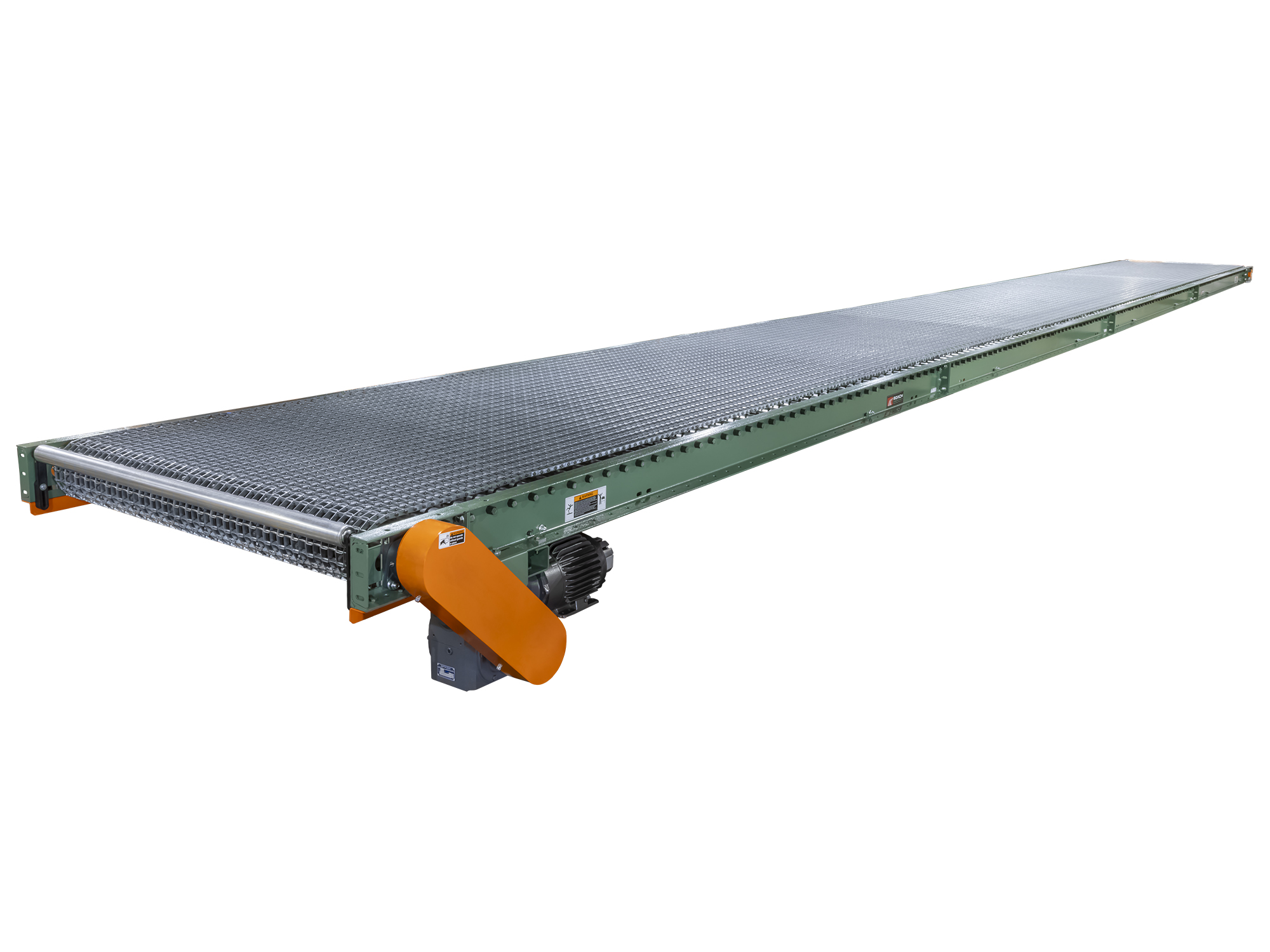

BELTING: 48" wide 1" x 1" galvanized belt (H1 heavy duty).

DRIVE PULLEY: 6″ dia. with 1-15/16″ dia. shaft on 50″ BF.

CARRIER ROLLERS: 3″ dia. x 11 ga. steel, model 251S.

END DRIVE: Allows one-direction (unit) operation; add optional center drive for reversible application.

BEARINGS: AMI bearings are precision, heavy duty, lubricated, ball bearing units with cast iron housings.

RETURN ROLLERS: 1.9″ dia. x 16 ga. steel, model 196S, adjustable.

BELT SPEED: 60 FPM, constant.

BED: 6" Structural Steel Channels.

FLOOR SUPPORTS: Optional

MOTOR DRIVE: 2 HP, 230/460/3, 60 cycle, ODP right angle gear motor.

SAFETY POP-OUT ROLLERS: Standard on both ends, 1.9″ dia x 12 ga. steel roller, model 192S on 15″-39″BF, 1.9″ x 9 ga. steel, model 199S on 45″-57″ BF.

ELECTRICAL CONTROLS: Optional

|