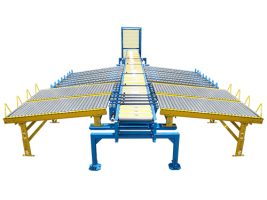

Model 138LRC features tapered rollers to maintain product orientation. Reversible, it is also commonly slave driven from 138LR and 138VP making it the ideal spur in light duty applications.

138LRCS | Live Roller Light Duty Spur Conveyor Curve

| Specifications | TREAD ROLLERS: 1.9″ dia. to 1-3/8″ dia. x 16 ga. tapered rollers, model 138T; 1-3/8″ dia. x 18 ga., model 138G w/ 5/16″ hex, galvanized straight tangent rollers. ROLLER CENTERS: 1-9/16″ measured at inside radius of unit. PRESSURE SHEAVES: Provides drive belt pressure to upper tread rollers. BELTING: “B” section V-belt. TAKE-UP: Screw type adjustable sheave with flat idler sheaves to maintain belt tension. TANGENTS: 12″ both ends on 60/30 degree unit; 18″ both ends on 45/45 degree unit. BED: 6″ x 1-1/2″ x 12 ga. formed steel channel frame. BEARINGS: End shafts are supported by precision, heavy duty, lubricated, ball bearing units with cast iron housings. ROLLER CHAIN: Drive shaft is driven by No. 50 chain. FLOOR SUPPORTS: Optional MOTOR DRIVE: 1/3 HP, 230/460/3, 60 cycle, ODP right angle gear motor, located under tangent straight section bed DRIVE LOCATION: Drive located on outside of curve. Specify left hand tangent length, right hand tangent length and drive location (“left hand drive” or “right hand drive”). NOTE: Drive hand determined with reference point located at outside of curve. For models slave driven (less drive), specify drive shaft location. CAPACITY: 300 lb. total distributed live load. SPEED: 60 FPM, constant. |

|---|

138LRCS

Model 138LRC features tapered rollers to maintain product orientation. Reversible, it is also commonly slave driven from 138LR and 138VP making it the ideal spur in light duty applications.

| Specifications | TREAD ROLLERS: 1.9″ dia. to 1-3/8″ dia. x 16 ga. tapered rollers, model 138T; 1-3/8″ dia. x 18 ga., model 138G w/ 5/16″ hex, galvanized straight tangent rollers. ROLLER CENTERS: 1-9/16″ measured at inside radius of unit. PRESSURE SHEAVES: Provides drive belt pressure to upper tread rollers. BELTING: “B” section V-belt. TAKE-UP: Screw type adjustable sheave with flat idler sheaves to maintain belt tension. TANGENTS: 12″ both ends on 60/30 degree unit; 18″ both ends on 45/45 degree unit. BED: 6″ x 1-1/2″ x 12 ga. formed steel channel frame. BEARINGS: End shafts are supported by precision, heavy duty, lubricated, ball bearing units with cast iron housings. ROLLER CHAIN: Drive shaft is driven by No. 50 chain. FLOOR SUPPORTS: Optional MOTOR DRIVE: 1/3 HP, 230/460/3, 60 cycle, ODP right angle gear motor, located under tangent straight section bed DRIVE LOCATION: Drive located on outside of curve. Specify left hand tangent length, right hand tangent length and drive location (“left hand drive” or “right hand drive”). NOTE: Drive hand determined with reference point located at outside of curve. For models slave driven (less drive), specify drive shaft location. CAPACITY: 300 lb. total distributed live load. SPEED: 60 FPM, constant. |

|---|

138LRCS

Accumulation Conveyors(9)

Accumulation

Belt Conveyors(10)

Belt Conveyors

Belt Driven Live Roller(7)

Belt Driven Live Roller

Chain Drag(5)

Chain Driven Live Roller(11)

Chain Driven Live Roller

Flexible Conveyors(2)

Flexible Conveyors

Gravity Conveyors(19)

Gravity Conveyors

Line Shaft(9)

Line Shaft

MDZ | Motor Driven Zone Accumulator(2)

MDZ | Motor Driven Zone Accumulator

Parts Conveyor(3)

Parts Conveyor

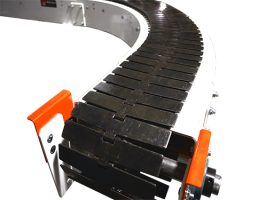

Plastic Belt(9)

Plastic Belt

Powered Roller(13)

Powered Roller

Singulation(1)

Singulation

Slat Conveyors(2)

Slat Conveyors

Transfers(8)

Transfers

Wire Mesh Belt(4)

Wire Mesh Belt

Barrel Conveyors(3)

Barrel Conveyors

Glass & Solar Handling(8)

Glass & Solar Handling

Heavy Duty Conveyors(16)

Heavy Duty Conveyors

Laundry(11)

laundry

Lumber & Door(5)

Lumber

MDR | Motor Driven Roller Smart Conveyors(6)

MDR | Motor Driven Roller Smart Conveyors

Sortation Conveyors(7)

Sortation Conveyors

Special Transfers(11)

Special Transfers

Stackers | Destackers(2)

Stackers/Destackers

Stops | Barriers | Walkovers(10)

Stops | Barriers | Walkovers

Tabletop Chain Conveyors(5)

Tabletop Chain Conveyors

Transfer Carts(9)

Transfer Carts

Turntables(17)

Turntables

Upenders | Downenders | Rollovers(10)

Upenders | Downenders | Rollovers

Vertical Conveyors(8)

Vertical Conveyors

Wheel & Tire Conveyors(4)

Wheel & Tire Conveyors