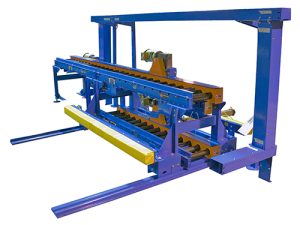

TREAD ROLLERS: 2-9/16″ dia. x 7 ga. steel rollers, model 297S with sprockets.

CHAIN DRIVE: Roller to roller with No. 60 roller chain.

ROLLER CENTERS: 4-1/2″, 6″, 9″ or 12″.

CENTER DRIVE: Reversible drive either side mounted or underside mounted (specify). Main drive roller is supported by precision, heavy duty, lubricated, ball bearing units.

BED: 4″ at 5.4 lbs. and 6″ at 8.2 lbs. structural steel channel frame. Bed sections attached with couplings and floor supports.

SPEED: 35 FPM, constant.

BEARINGS: Removable type, heavy duty ball bearings, zinc-plated, grease packed, labyrinth sealed. Roller bearings provide roller capacity of 540 lbs. per roller (maximum).

CHAIN GUARD: The chain drive is completely enclosed along the entire length of the conveyor.

BED LENGTHS (4-1/2″ or 9″ RC): Intermediate bed section lengths 3′-0″, 3′-9″, 4′-6″, 5′-3″, 6′-0″, 6′-9″, 7′-6″, 8′-3″, 9′-0″ and 9′-9″ increments. Minimum overall conveyor length with drive 5′-3″. Maximum overall conveyor length: 58′-6″ with 4-1/2″ RC; 78′-0″ with 9″ RC.

BED LENGTHS (6″ or 12″ RC): Intermediate bed section lengths are available in 1′-0″ increments. Minimum overall conveyor length with drive 5′-0″. Maximum overall conveyor length 80′-0″.

MOTOR DRIVE: 3/4 HP, 230/460/3, 60 cycle, ODP right angle gear motor.

FLOOR SUPPORTS: Optional

ELECTRICAL CONTROLS: Optional

|