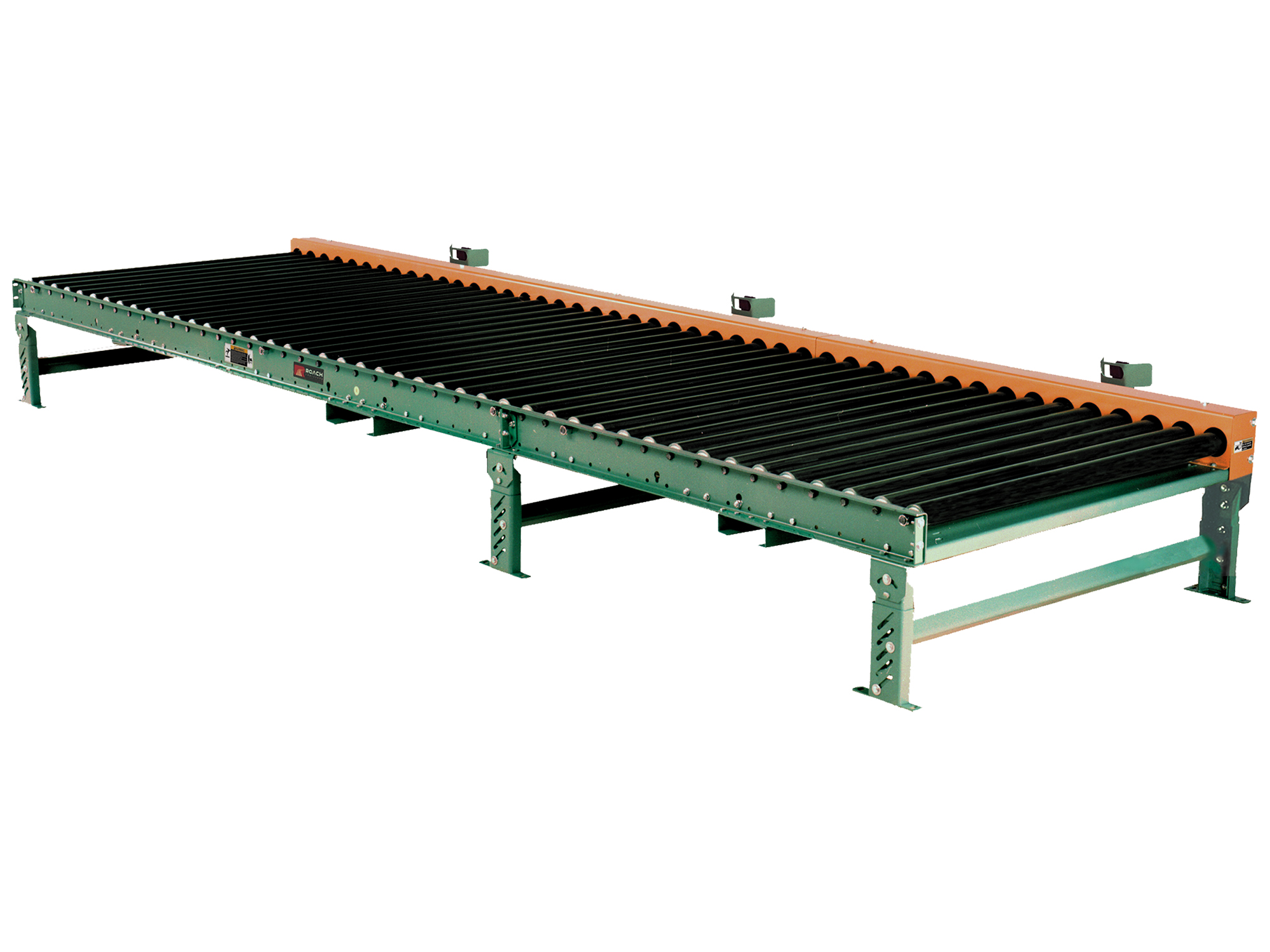

TREAD ROLLERS: 2.5 ” dia. x 11 ga., model 251S.

CHAIN DRIVE: Roller-to-roller No. 40 roller chain. Zone-to-zone No. 60 roller chain.

CHAIN GUARD: All chains are completely enclosed along the entire length of conveyor.

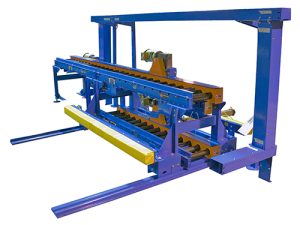

CENTER DRIVE: Drive either side mounted or underside mounted (specify). Drive shafts are supported by precision, heavy duty, lubricated, ball bearing units.

ROLLER CENTERS: 4″ or 6″ RC ONLY.

SPEED: 35 FPM, constant.

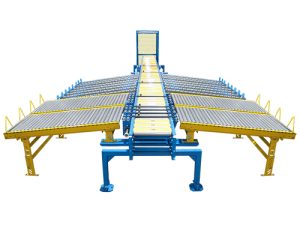

ACCUMULATION ZONE: 5′-0″ zone lengths, zone singulation operation, photo electric sensor controlled zones with separate drives on each zone.

BED: 7-1/2″ x 1-1/2″ x 7 ga. and 5 ” x 1-1/2″ x 7 ga. formed steel channel frame. Bed sections are bolted together with butt couplings and floor supports.

FLOOR SUPPORTS: Optional

BEARINGS: Removable type, heavy duty ball bearings, zinc-plated, grease packed, labyrinth seal.

FRL: Unit is provided with filter, regulator and lubricator with 3/8″ ports for 60 PSI operational pressure.

MOTOR DRIVE: 1/2 HP, 230/460/3, 60 cycle, ODP right angle gear motor.

CAPACITY: 1000 lbs./ft. up to a maximum of 3000 lb. pallet load.

ELECTRICAL CONTROLS: Optional

|