Convert Roller Sections for Bidirectional Diverting

Easily Installs into Any Brand Frame with No Modifications

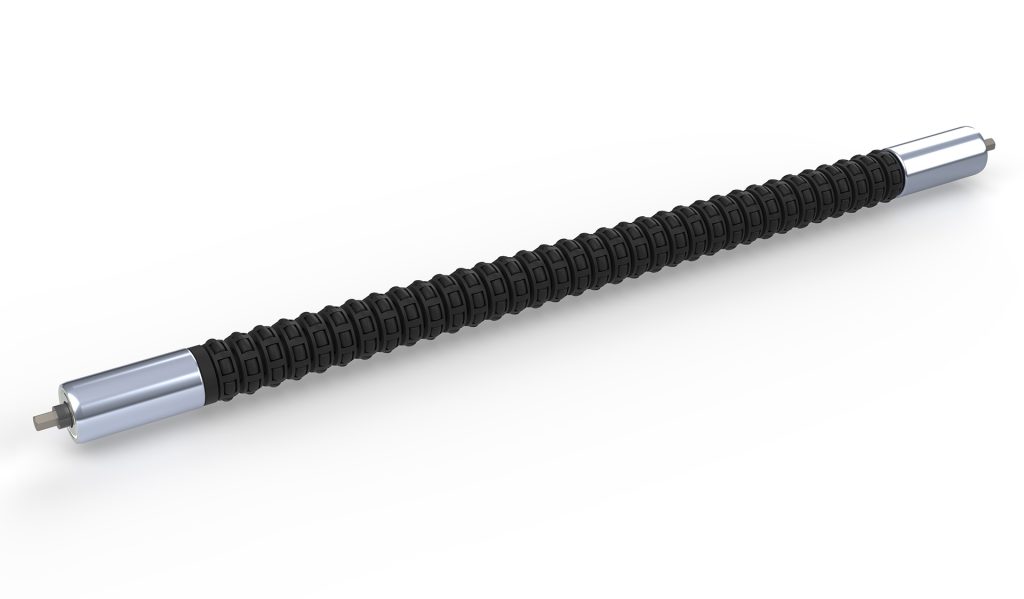

Replaces Any 1.9" O.D. Grooved Rollers

Reduces Manual Push Fatigue up to 75%

Ball Transfer Like Product Reorientation

The CrossX™ Easy Transfer Roller converts a standard roller conveyor section into a transverse top push configuration quickly and cost-effectively, delivering the functionality of a transverse roller top belt conveyor without the higher investment.

Unlike traditional rollers that only move items forward, the innovative CrossX™ Roller enables smooth, controlled redirection of packages and containers across conveyor lines, drastically improving line flexibility. The CrossX™ system is a simple upgrade that adapts any brand 1.9″ O.D. grooved roller conveyor into an ergonomic, easy-push diverting solution. Installation is fast, with CrossX™ Rollers dropping directly into any brand conveyor frame with no required modifications.

This game-changing, bidirectional roller system is designed for parcel and package handling environments where workers frequently push items across conveyor lines. By reducing the force required to push packages by up to 75%, the CrossX™ Roller relieves worker fatigue, minimizes strain, and enhances overall efficiency. The drop-in replacement also allows for easy product reorientation across the conveyor surface, allowing cartons, totes, and irregular loads to change direction smoothly in a manner similar to a ball transfer.

Whether optimizing existing lines or designing new configurations, the CrossX™ Easy Transfer Roller delivers smooth transfers, durable construction, and an ergonomic solution that grows with your

operation.

Applications

- Manual transfer zones

- Cross belt package redirection

- Sortation support areas

- Intersecting conveyor lines

- Operator assisted package handling

Industries

- Parcel and sortation

- E-commerce fulfillment

- Warehousing and logistics

- Manufacturing and packaging

- Third party logistics operations

See how CrossX™ rollers enhance material handling operations, from sortation integration to manual transfers.

CROSSX™ MANUAL PUSH

Comparison of manual carton transfers across standard rollers versus CrossX™ rollers.

CROSSX™ HIGH-SPEED SORTER

CrossX™ rollers work with a high-speed sorters to support controlled lateral package movement.

CROSSX™ EASY DROP-IN

Removing standard rollers and installing CrossX™ is simple and easy.

SMOOTH PRODUCT ORIENTATION

PUSH EFFORT REDUCED UP TO 75%

CROSSX™ ROLLER OPTIONS

CrossX™ Gravity Roller

Cartons and totes are easily pushed sideways with minimal effort while continuing to move along a gravity conveyor.

CrossX™ Grooved Roller

Smooth side-to-side package movement while keeping O-ring drive bands in place for consistent conveyor operation.

CrossX™ Poly-V Roller

Easy lateral package movement while maintaining positive drive engagement in powered poly-V conveyor lines.