WIRE MESH BELT

Applications

- Oven and heat processing lines

- Cooling and drying conveyors

- Washdown and sanitation systems

- Spray coating or rinsing operations

- Product curing or conditioning processes

Industries

- Food processing and baking

- Packaging and converting

- Industrial manufacturing

- Chemical and coating operations

- Automotive and metalworking processes

Wire mesh belt conveyors are used where product exposure to air, heat, cooling, or liquids is required during conveying. These conveyors use an open metal belt constructed of woven wire or formed mesh that supports product while allowing airflow, drainage, or spray access through the belt surface. They are commonly applied in oven, washdown, cooling, and drying processes where traditional solid belts are not suitable. Open bed and heavy duty roller bed configurations allow the conveyor to be matched to product weight, operating temperature, and support requirements.

Open bed wire mesh belt conveyors provide maximum access beneath the belt, allowing air movement or liquid sprays to pass freely through the conveying surface. This design is frequently used in drying, cooling, coating, or wash applications where uniform exposure is necessary. Heavy duty roller bed wire mesh belt conveyors add additional belt support for higher load capacities or longer conveyor lengths while maintaining the open characteristics of the wire mesh belt. Optional components such as spray down duty motors and reducers support operation in wet or harsh environments.

Wire mesh belt conveyors are typically selected based on belt material, wire diameter, mesh opening, and drive configuration to suit the process conditions. Their construction supports operation in high or low temperature environments and in applications involving oily, wet, or abrasive products. These conveyors are often integrated into continuous process lines where durability, cleanliness, and consistent belt tracking are required.

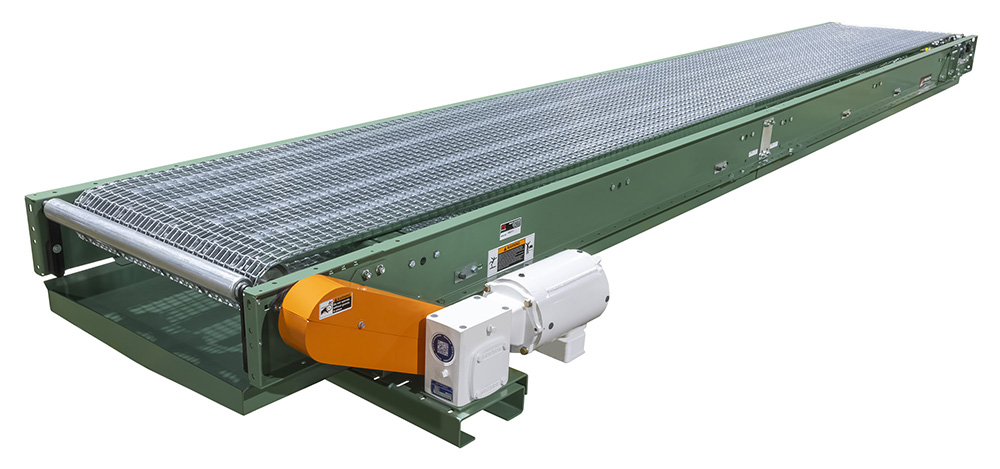

700SBW | Wire Mesh Belt Conveyor

The 700SBW model is a general purpose wire mesh belt conveyor designed to move hot, cold, oily, or otherwise challenging products through continuous process environments. Its woven wire mesh belt is supported within a formed channel frame with UHMW wear strips and adjustable return rollers to promote reliable belt alignment and long service life.

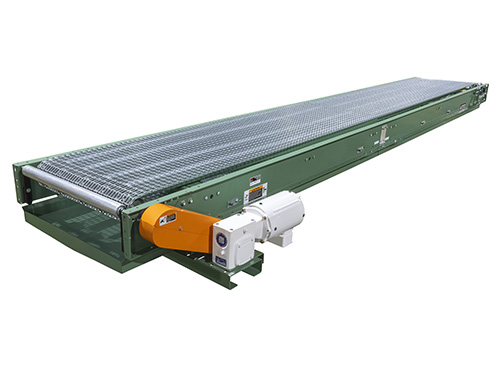

700SBO | Open Bed Style Wire Mesh Belt Conveyor

The 700SBO open bed style wire mesh belt conveyor uses an open wire mesh surface to allow airflow, liquid sprays, and heat transfer through the belt surface during conveying. This design supports operations where drying, cooling, or spray application is required as part of a process line. The frame includes an open channel bed with UHMW wear strips and adjustable return rollers to maintain consistent mesh belt tracking and support.

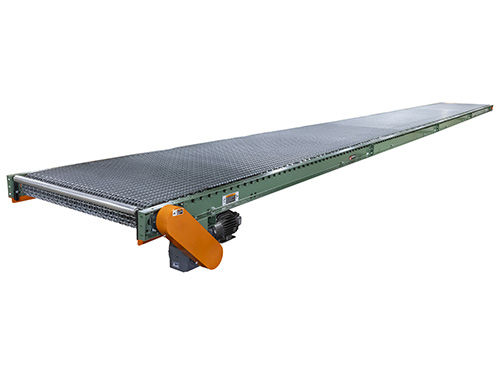

651RBW | Heavy Duty Roller Bed Conveyor with Wire Mesh Belt

The 651RBW heavy duty roller bed conveyor with wire mesh belt combines the open belt design with additional roller support beneath the mesh surface to accommodate heavier unit loads. The conveyor uses a robust structural channel frame and precision AMI bearings to support constant speed movement of loaded products through environments such as oven, cooling, or oily part handling.