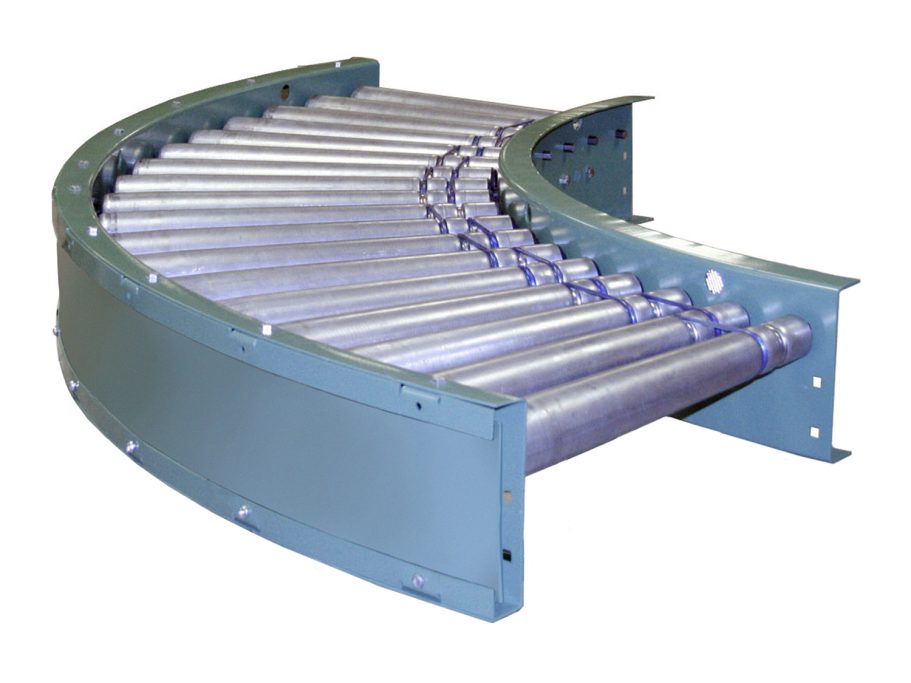

The 796PRAC configures the 796PRA into curved sections with tapered rollers and indirect drive logic, maintaining accumulation control through curves. Photoeye sensors actuate zones to stop and start product movement, supporting controlled queuing through non-linear layouts.

Rollers are set low in the 7-inch frame, providing stable conveying surfaces in curved paths. This model is appropriate where facility layouts require directional changes while sustaining zero pressure accumulation performance.

Applications

- Carton and tote conveying

- Accumulation and buffering between processes

- Sortation and routing operations

- Order fulfillment and distribution

- Packaging and labeling lines

Industries

- Distribution and warehousing

- E-commerce and fulfillment

- Manufacturing and assembly

- Packaging operations

- Logistics and material handling

SPECIFICATIONS

| TREAD ROLLERS | 2-1/2 in. dia. to 1-11/16 in. dia. x 14 ga. steel tapered rollers, model 254T |

| DRIVE BELT | 3/16 in. dia. polyurethane belts, nominal 15 lbs per roller drive |

| CAPACITY | 15 lbs per roller or up to 70 lbs per zone |

| SPEED | 60 FPM constant |

| ROLLER CENTERS | 3 in. |

| BED / FRAME | Formed steel curve frame with tapered roller configuration |

| ACCUMULATION | Zone singulation operation, 24 in. zone length, photoeye actuated |

| MOTOR DRIVE | Driven by 24V DC Powered Roller |

| BEARINGS | Precision ABEC bearings |

| DC POWER SUPPLY | 24 volt fixed output required |

DETAILS

ACCESORIES / OPTIONS

Zone Lengths

Floor Supports

Ceiling Hangers

Speed

Motors

Defused Smart Zone®

WARRANTY

Electrical: 12 Months

Mechanical: 12 Months

SERVICES

Technical Support

Installation & Service

Preventative & Routine Maintenance

Application Support

Operator & Maintenance Training