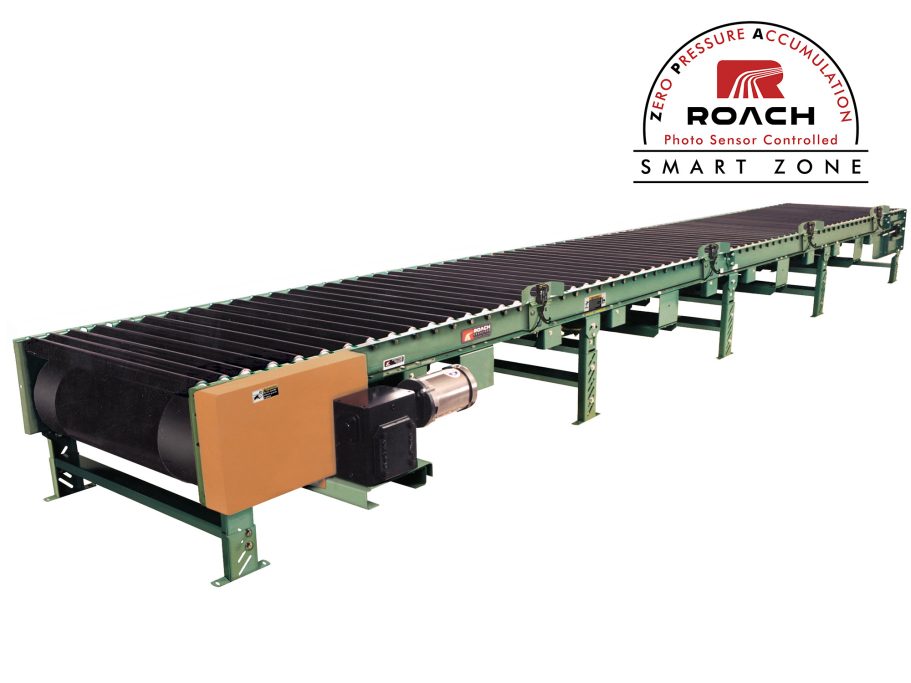

The SZ251ZPA heavy duty Smart Zone® accumulator is engineered to manage significantly higher loads, accommodating heavy containers, large boxes, and palletized units using zero pressure zone singulation. Photoelectric sensors replace sensor rollers, enabling each accumulation zone to detect product presence without minimum weight limitations and preventing contact between queued products. This design minimizes product damage and improves handling consistency in rugged material handling environments.

The conveyor structure incorporates larger diameter tread rollers and robust bearings suited for heavy applications, along with precise pneumatic actuation for extended zone lengths. Heavy duty construction elements, including a formed steel channel frame and high-capacity drive system, make this conveyor applicable to industrial, distribution, and high-volume handling systems where higher mass handling and controlled accumulation are essential.

Applications

- Product buffering between processes

- Merging and singulation of cartons or totes

- Accumulation before sortation, labeling, or inspection

- Controlled release into packaging or palletizing equipment

- Staging product for shipping and order fulfillment

Industries

- Distribution and fulfillment operations

- Manufacturing and assembly lines

- Packaging and material handling systems

- Food and beverage processing

- Automotive and industrial manufacturing

SPECIFICATIONS

| BF | 39", 43", 51", 57" |

| CONVEYING SURFACE | 42", 46", 54", 60" |

| TREAD ROLLERS | 2.5" dia. x 11 ga. steel, model 251S. |

| PRESSURE ROLLERS | 1.9" dia. x 16 ga. steel, model 196S; 27" BF for all widths. |

| BELTING | 12" wide black PVC-120.COS. |

| SIDE MOUNT END DRIVE | Allows one direction unit operation. |

| DRIVE PULLEY | 12" dia., with 1-15/16" dia. shaft, crowned and fully lagged. |

| TAIL PULLEY | 8" dia. with 1-3/16" dia. shaft, crowned. |

| RETURN ROLLERS | 1.9" dia. x 16 ga. steel, model 196S, adjustable. |

| BED / FRAME | 5" x 1-1/2" x 3/16" formed steel channel frame slotted for tread rollers to pop-out. When unit is installed at 7'-0" elevation or higher, rollers must be retained in conveyor frame. Specify desired elevation. Bed sections attached with couplings and floor supports. |

| BEARINGS | All pulley bearings are precision, heavy duty, lubricated, ball bearing units with cast iron housings. |

| SPEED | 35 FPM, constant. |

| ACCUMULATION | 5'-0" long zones with zone singulation operation. 1'-6" of live roller over end plates at each end of conveyor remains “live” during operation (# of zones x zone length + 3'-0" + overall conveyor length). Zones are pneumatically actuated by using photo electric sensors. |

| FRL | Unit is provided with filter, regulator, lubricator with 3/8" ports for 60 PSI operational pressure. |

| FLOOR SUPPORTS | Optional. |

| MOTOR DRIVE | 1/2 HP, 230/460/3, 60 cycle, Super "E" right angle gear motor. |

| ROLLER CHAIN | No. 60 chain provided at drive pulley. Chain take-up provided on motor base. |

| ELECTRICAL CONTROLS | Optional. |

DETAILS

ACCESORIES / OPTIONS

Slug Release

Floor Supports

Guard Rails

Speed

Motors

Defused Sensors

Controls

WARRANTY

Electrical: 12 Months

Mechanical: 12 Months

SERVICES

Technical Support

Installation & Service

Preventative & Routine Maintenance

Application Support

Operator & Maintenance Training