WHEEL & TIRE HANDLING

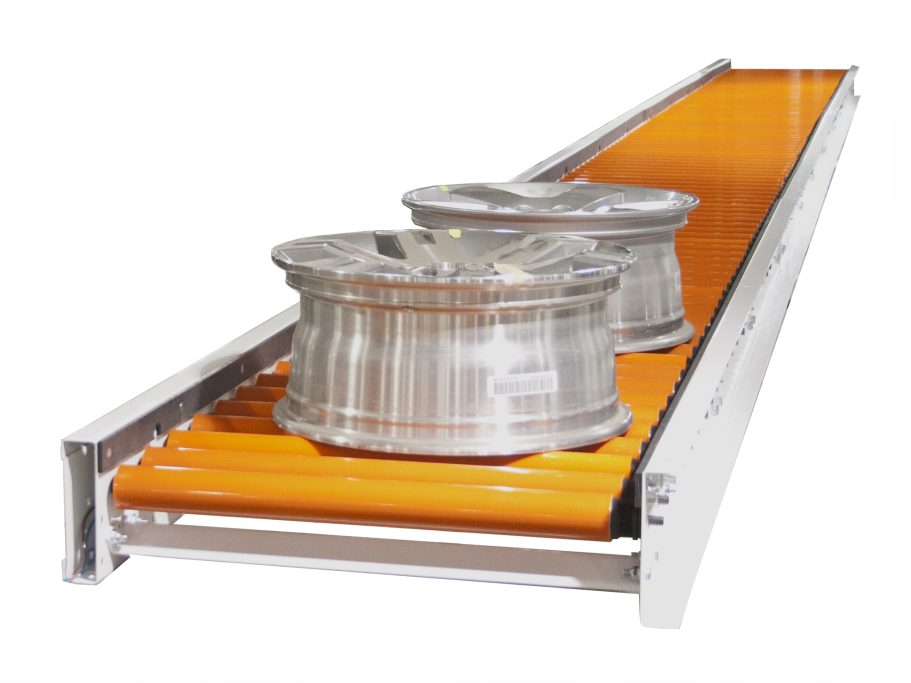

Wheel and tire handling conveyors are used in manufacturing and distribution environments to transport wheels, tires, and wheel assemblies with controlled positioning and surface protection. These systems are designed to manage round, flexible, or heavy products while maintaining alignment and spacing throughout the handling process. Conveyor designs are selected based on product condition, temperature, and integration with automated equipment.

Non marking conveyor surfaces with urethane covers are commonly used to protect finished wheels and tires from surface damage during transport. For high temperature environments, chain drag conveyors rated up to 700 degrees are used to handle heated components exiting curing, coating, or thermal processing operations. Tire centering features are often incorporated to align products accurately for robotic pick and place or automated transfer.

Wheel and tire handling conveyors are typically engineered as part of integrated production lines rather than standalone units. Conveyor type, orientation, and control logic are configured to support consistent product flow and reliable positioning. These systems are designed for continuous operation in demanding industrial environments where durability and precision are required.

Applications

- Transporting tires through inspection and staging areas

- Moving wheels and assemblies between processing steps

- Feeding tires to robotic handling systems

- Conveying heated components after curing or coating

- Accumulating products prior to packaging or shipment

- Supporting automated wheel and tire assembly lines

Industries

- Automotive manufacturing

- Tire production and processing

- Transportation equipment manufacturing

- Industrial assembly operations

- Warehousing and distribution

- Heavy equipment manufacturing

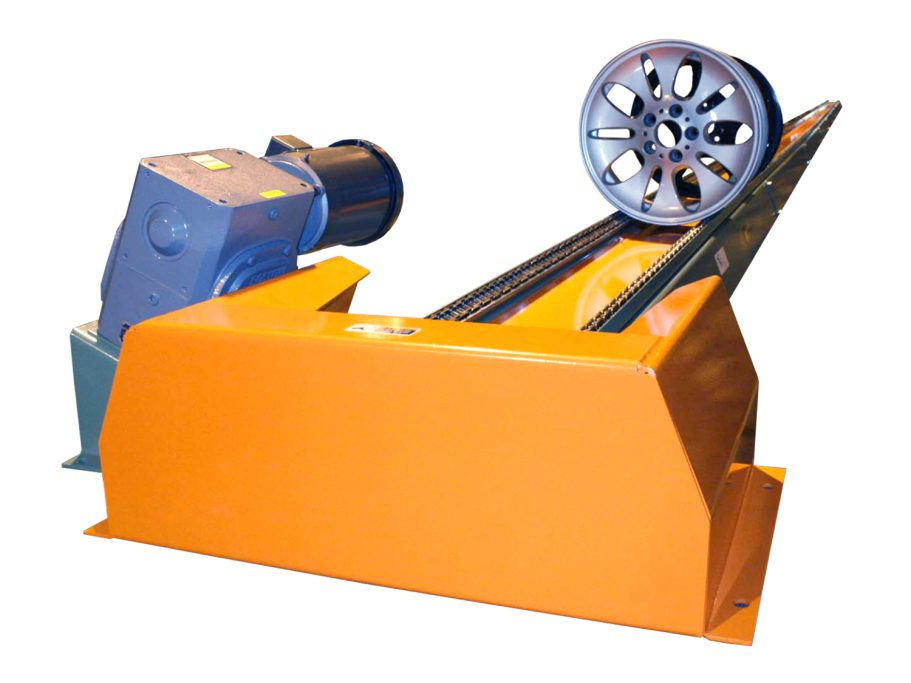

700° Chain Drag 280

This Chain Drag was designed to withstand a 700 degree product. The product is wheels varying in diameter from 16” to 22” standing on end weighing 50 lbs. each. Model 280 chain drags on 8-1/2” centers move the high temperature product down a 100’ long line during the cooling process. These No. 80 Flat Bar Chains are set on 67-1/2” degree angles to move the wheels at 30 fpm.

ref#408986

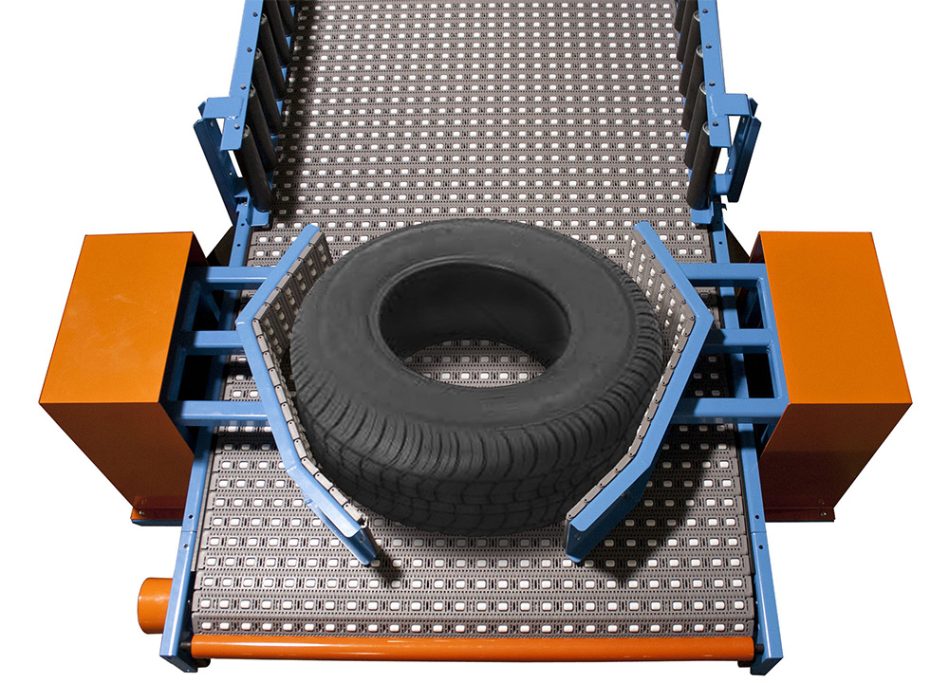

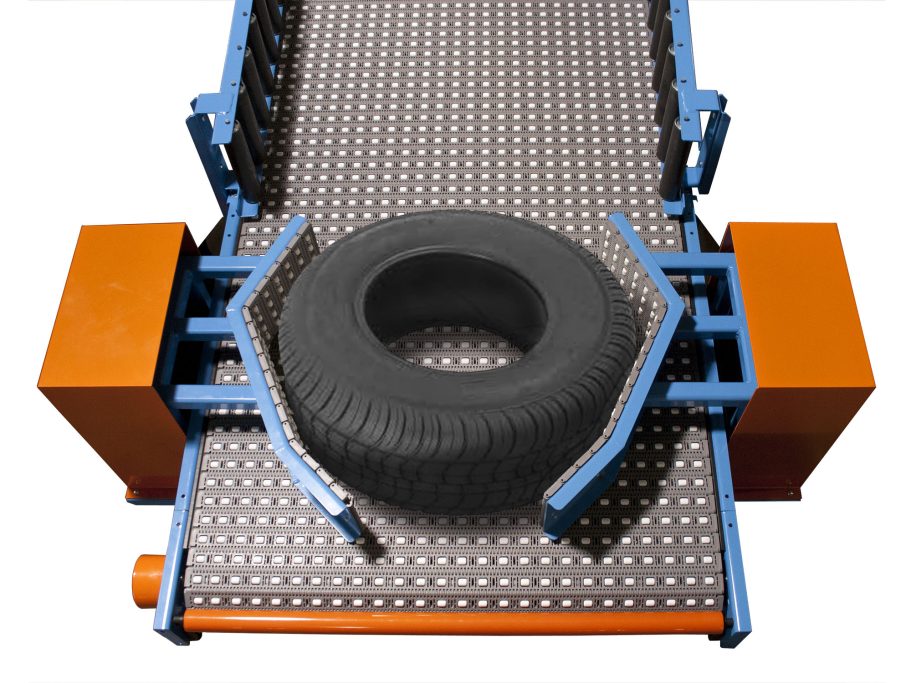

Tire Centering Device

The tire centering device will align tires in the center of the conveyor to be unloaded by robot. As tires move into the centering area the paddles clamp onto the tire placing it in the center. The 52” wide series 400 roller top belt allows the conveyor to operate continuously while the tire is clamped in place. Roller top belt has also been attached to the face of the paddles to aid in alignment.

ref#491803

Vertical Roller Tire Chute

The vertical roller tire chute is constructed of 251S rollers mounted in a structural steel curved frame with a tire centering device. The centering device is adjustable in 1 inch increments to accommodate multiple size tires on the conveyor line as they pass through. A special support base was designed to distribute the shock loading as tires are dropped onto the conveyor.

ref#523837