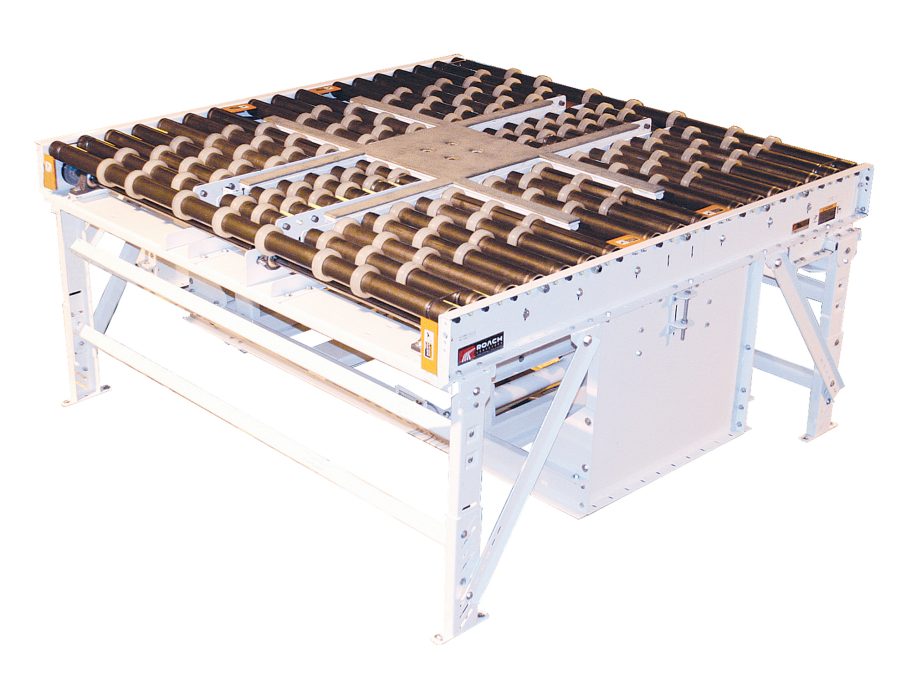

GRID TURNTABLES

Grid turntable conveyors are powered material handling devices designed to rotate products to a new orientation within a conveyor system. These units use an open grid-style deck that supports heavy or irregular loads while allowing debris, dust, or moisture to pass through. Grid turntables rotate either continuously or in indexed positions, enabling controlled direction changes without disrupting upstream or downstream conveyor flow.

Medium and heavy duty grid turntables are commonly used where product orientation, load alignment, or routing flexibility is required. Continuous rotation designs support constant motion for steady flow conditions, while indexing designs rotate to precise positions for controlled transfer and positioning. Both configurations are engineered for industrial environments and integrate with belt, roller, and chain-driven conveyors.

Grid turntables are suited for applications requiring durability, positional accuracy, and compatibility with demanding material handling systems. Construction options support varying load capacities, rotational speeds, and control requirements, making these conveyors adaptable to a wide range of operational layouts.

Applications

- Rotating heavy or irregular loads to change travel direction within a conveyor system

- Aligning products for transfer between belt, roller, or chain driven conveyors

- Supporting controlled indexing for precise load positioning

- Maintaining continuous product flow through direction changes

- Handling loads that generate debris, dust, or moisture during transport

- Serving as routing points within complex conveyor layouts

- Orienting products prior to processing, inspection, or downstream handling

Industries

- Heavy manufacturing and industrial fabrication

- Metalworking and machining operations

- Building materials and construction products

- Automotive and transportation equipment

- Glass and solar manufacturing environments

- Recycling and bulk material handling

- Warehousing and automated material handling systems

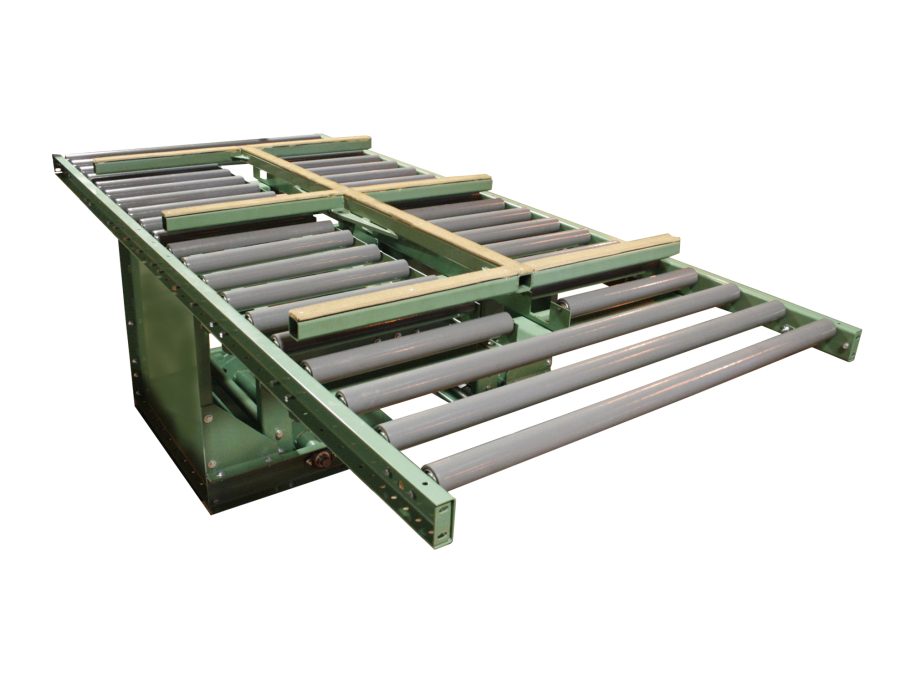

Non-Marking Grid Turntable

This Grid Turntable is mounted in a 196 gravity conveyor with 3/16″ thick gray PVC covering on the tread rollers. The grid arms are covered with non-marking belt which compliment the PVC covered rollers to avoid damaging the finish of the product. The grid is pneumatically raised and can be manually turned 180 degrees by the operator.

ref#417991

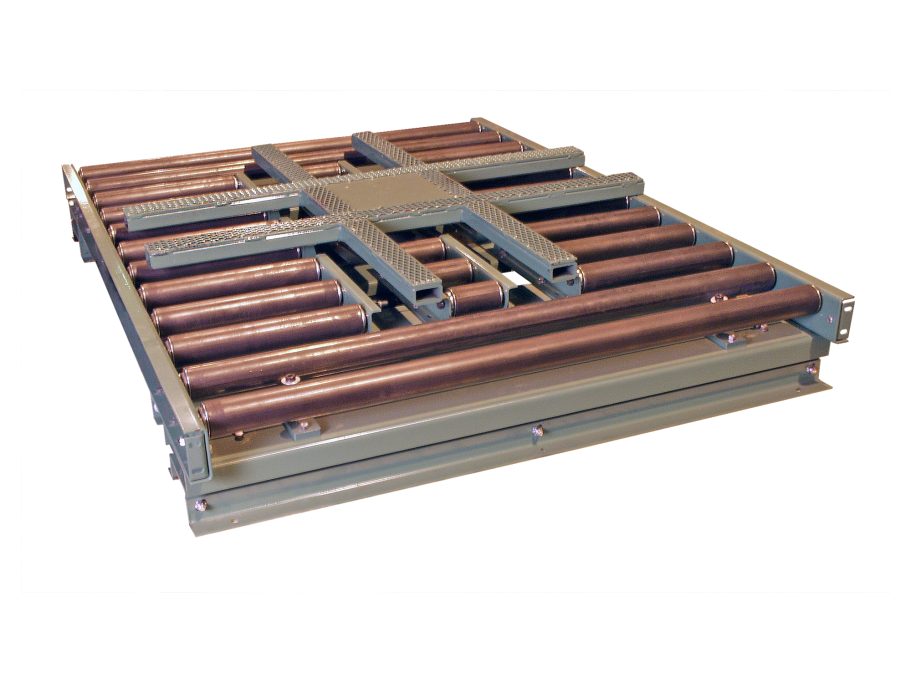

Pneumatic Grid Turntable

This grid turntable was designed for low elevations. The product is manually positioned and centered above the grid. The conveyor is then lowered leaving the product sitting on top of the grid turntable. The turntable is then rotated 90 degrees and the conveyor is raised to pick the product up. The product can now be manually discharged.

ref#389209