TRANSFER CARTS

Transfer carts are used in material handling systems to move heavy loads laterally between conveyor lines, workstations, or processing zones. These carts travel along a fixed track or guide path and provide controlled positioning for loads that must be transferred across multiple lanes or aisles. Transfer carts are commonly applied where traditional conveyor layouts are not practical due to space constraints or process requirements.

Heavy duty transfer carts typically travel along a tracking guide using pneumatic pistons to control movement and positioning. Top mounted modules such as chain driven live roller, powered roller, belt conveyors, and turntables can be integrated to support product transfer and orientation. Pneumatic lift mechanisms raise or lower the transfer surface to align with adjacent conveyors, allowing smooth load transitions.

Transfer carts are engineered as part of integrated material handling systems and include safety features to support reliable operation. Pneumatic stops control load position, while safety bumpers and emergency stop controls provide protection for personnel and equipment. Load capacity, travel distance, and control logic are configured to match application requirements and operating conditions.

Applications

- Transferring loads between parallel conveyor lines

- Moving products across aisles or process zones

- Positioning loads for machining or assembly

- Supporting flexible manufacturing layouts

- Feeding and discharging automated equipment

- Handling heavy or oversized products

Industries

- Heavy manufacturing and fabrication

- Automotive and transportation equipment

- Metals processing and machining

- Building materials manufacturing

- Warehousing and material handling

- Industrial equipment production

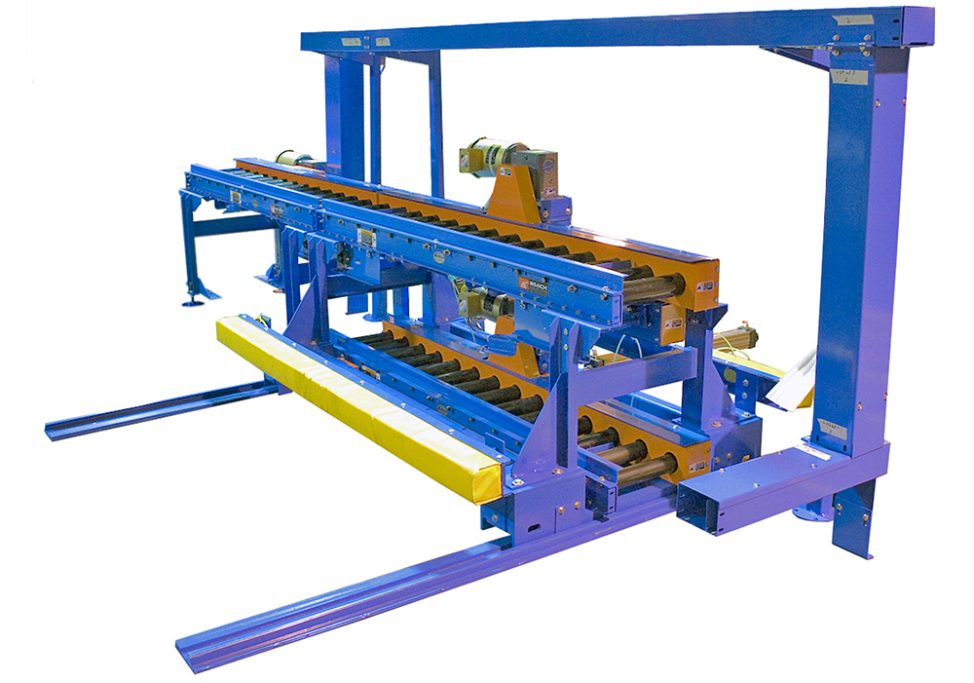

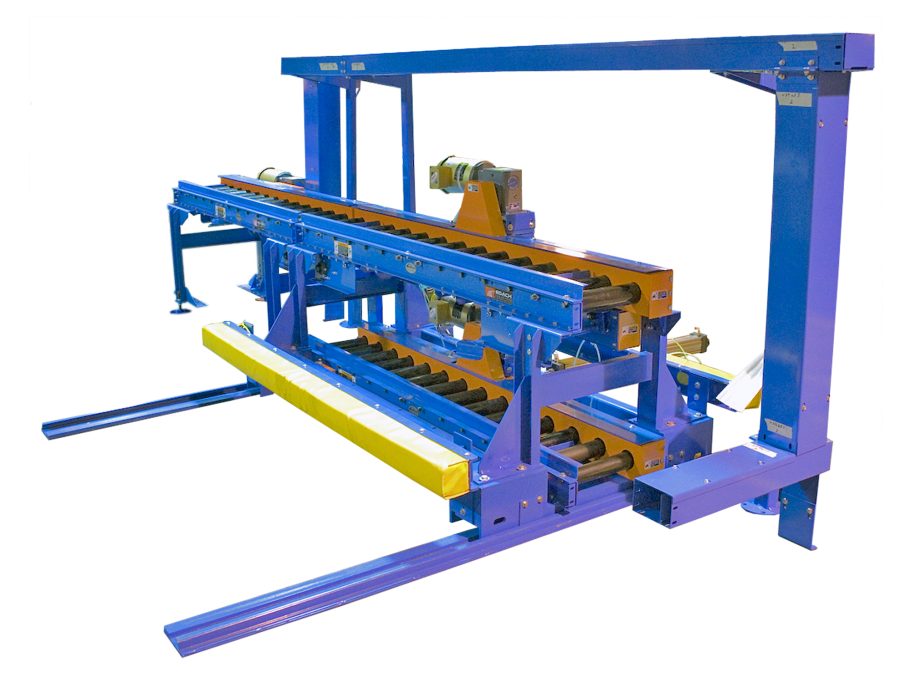

Dual Lane Transfer Cart with Turntable

This is a manually operated turntable combined with a transfer cart. Automotive parts on a pallet are conveyed onto the turntable. This turntable has 2-199S gravity conveyors spaced apart to give an effective 50” BF. To contain the product these gravity units have heavy duty butt end stops at the discharge end and dual blade stops at the infeed end. The operator can release the lock for the turntable and use the 4 post to manually rotate the product for inspection. After inspection the product is then moved by the transfer cart along the floor track to the next conveyor line. ref#510863

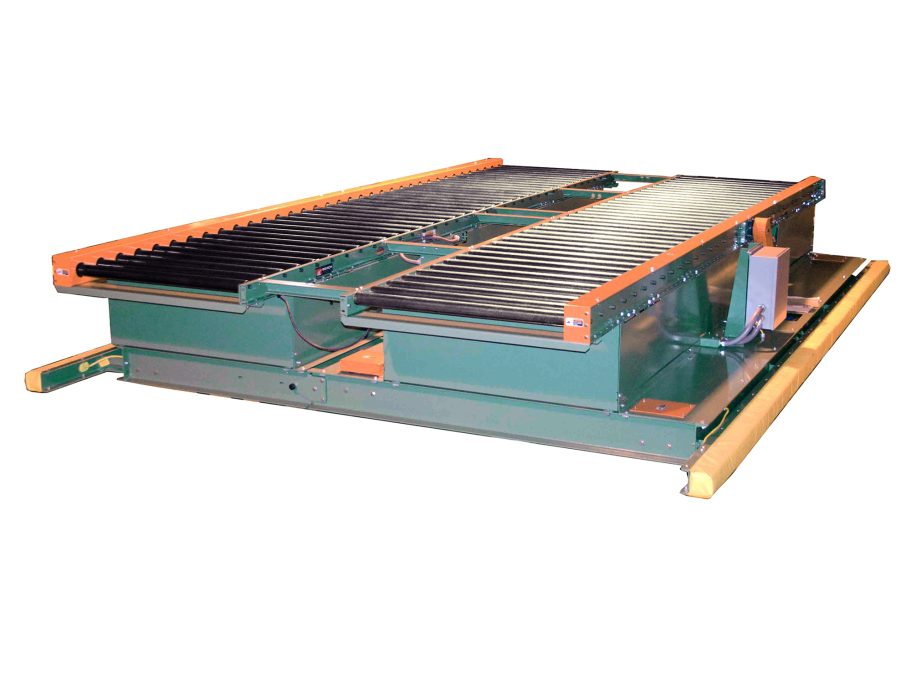

Low Profile IPT

The Low Profile IPT is a transfer cart topped with a powered roller conveyor turntable in a compact elevation. Used to move and rotate large products. The powered rollers assist in the transfer on and off of the turntable. The rollers feature pneumatic roller stops to prevent roller and product movement during cart motion. Also features safety-stop bumpers in case of path blockage while the cart is in motion.

#ref483110

Low-Pro Transfer Cart

This Low Profile Transfer Cart receives product racks at a low elevation of 9” for easier manual loading of the racks. It then travels to the receiving conveyor, elevates to 19” via scissor-lift, and transfers the loaded racks onto conveyor. The conveyor and transfer cart are powered by MDR (Motorized Drive Rollers).

#521599

Low-Pro Transfer Cart Loading Cutout

This Low Profile Transfer Cart conveys empty product racks to a loading station where it elevates. Personnel then load the racks from back to front by entering the recessed area of the conveyor and working back out. The cart then lowers and moves to a receiving conveyor to transfer the loaded rack. The conveyor and transfer cart are powered by MDR (Motorized Drive Rollers).

#ref521595

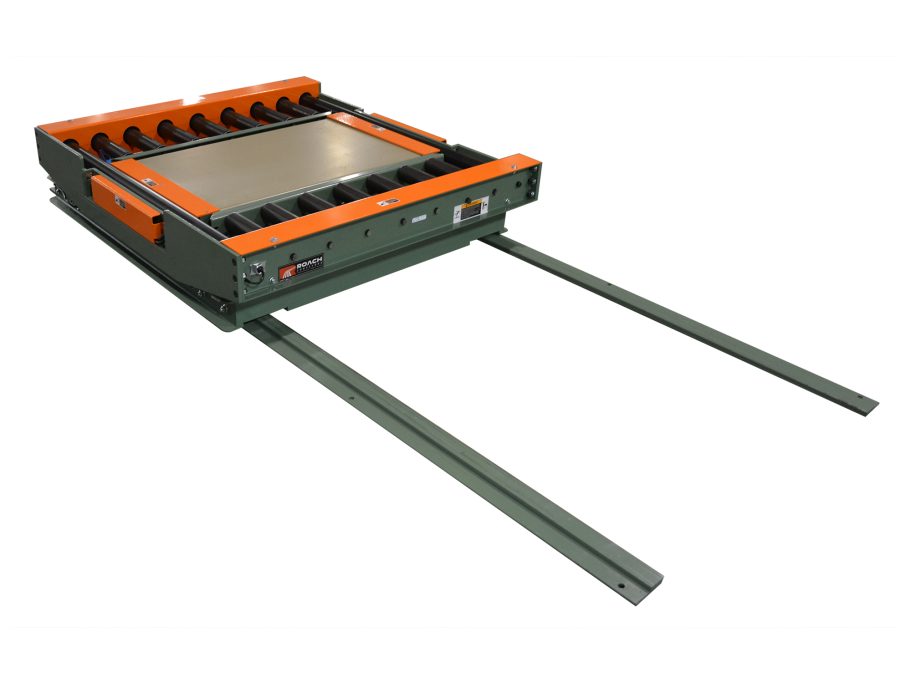

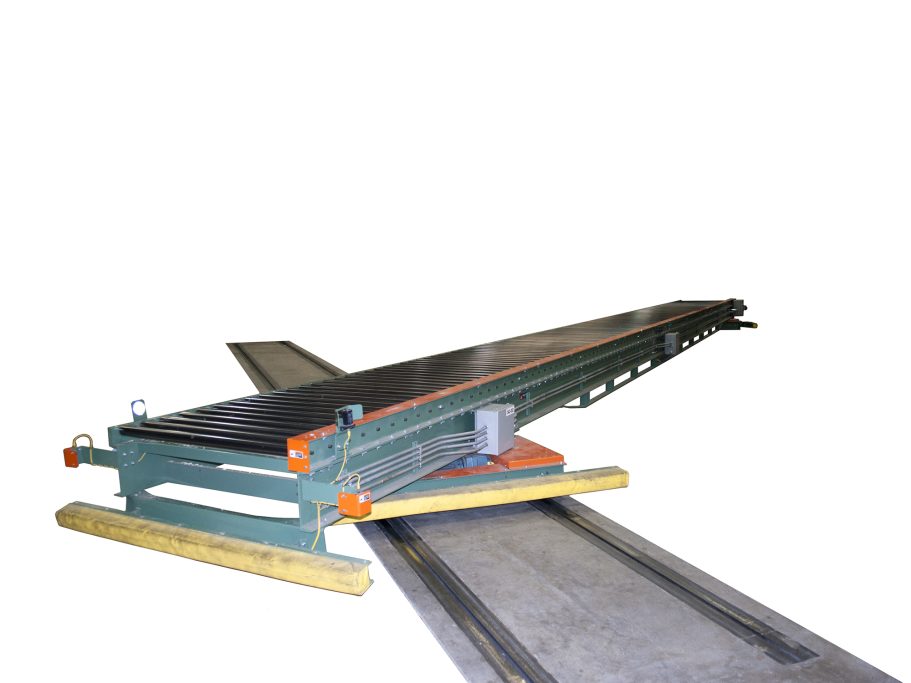

Powered Transfer Cart

The Powered Transfer Cart is mounted at the end of two conveyor lines. Product is transferred from one conveyor to the other. V-Groove casters travel along the 6’ inverted-angle track. Fixtures will be mounted to lifting plates between the rollers to raise and lower product on and off the transfer.

ref#501889