SPECIALTY TRANSFERS

Specialty transfer conveyors are used in material handling systems to move products between conveyor sections, change travel direction, or transfer loads across gaps where standard conveyors are not suitable. These conveyors support controlled movement between belts, rollers, or chain driven systems while maintaining product orientation and spacing. Specialty transfers are commonly applied where product size, weight, or stability requires precise handling during transitions.

Specialty transfer designs include powered and non powered mechanisms that lift, shift, rotate, or slide products from one conveyor to another. Transfer motion is synchronized with upstream and downstream conveyors to maintain predictable flow and minimize product disruption. Transfer geometry and actuation method are selected based on product characteristics, required direction change, and system layout.

Specialty transfer conveyors are typically integrated as part of a larger material handling system rather than used as standalone equipment. Control logic, timing, and guarding are configured to support continuous operation and safe interaction with adjacent conveyors. These systems are engineered to address application specific challenges where standard transfer methods are not effective.

Applications

- Transferring products between perpendicular conveyors

- Moving items across gaps or interruptions in conveyor lines

- Shifting loads between different conveyor surfaces

- Supporting infeed and discharge for automated equipment

- Positioning products for downstream processing

- Managing transitions in complex conveyor layouts

Industries

- Manufacturing and assembly operations

- Distribution and fulfillment centers

- Packaging and material handling systems

- Automotive and transportation equipment

- Food and consumer goods production

- Industrial processing facilities

7-Strand Belt Transfer

The 7 strand transfer is moving steel, in the flat, off of a line shaft conveyor to be moved to the next stage of the manufacturing process. These strands have a 2” wide Nitrile roughtop belt to avoid scratching the metal while being transferred and have UHMW post which serve as a product stop. These 7 strands are spaced at varying distances to accommodate multiple lengths of metal up to 32 ft. weighing as much as 150 lbs.

ref#486161

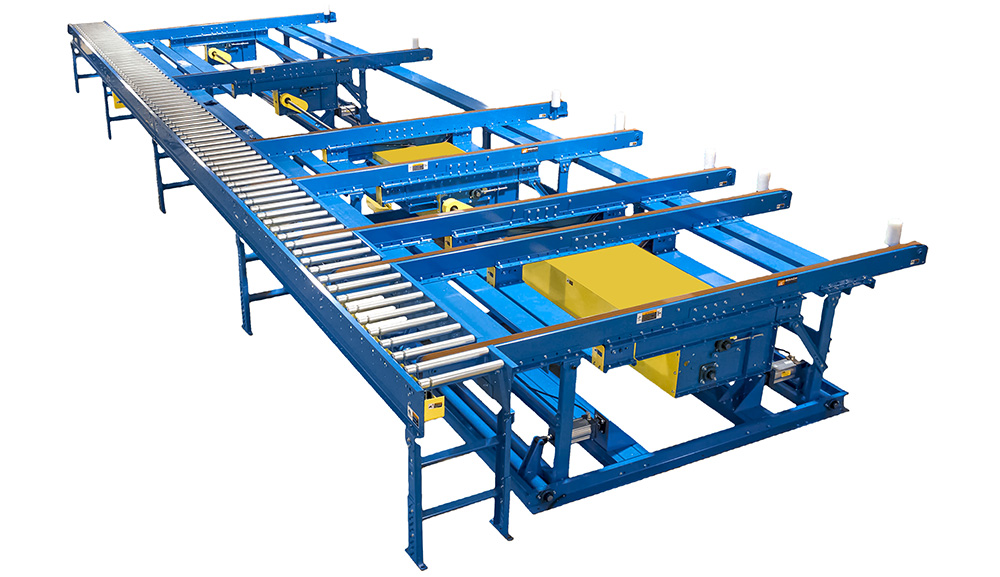

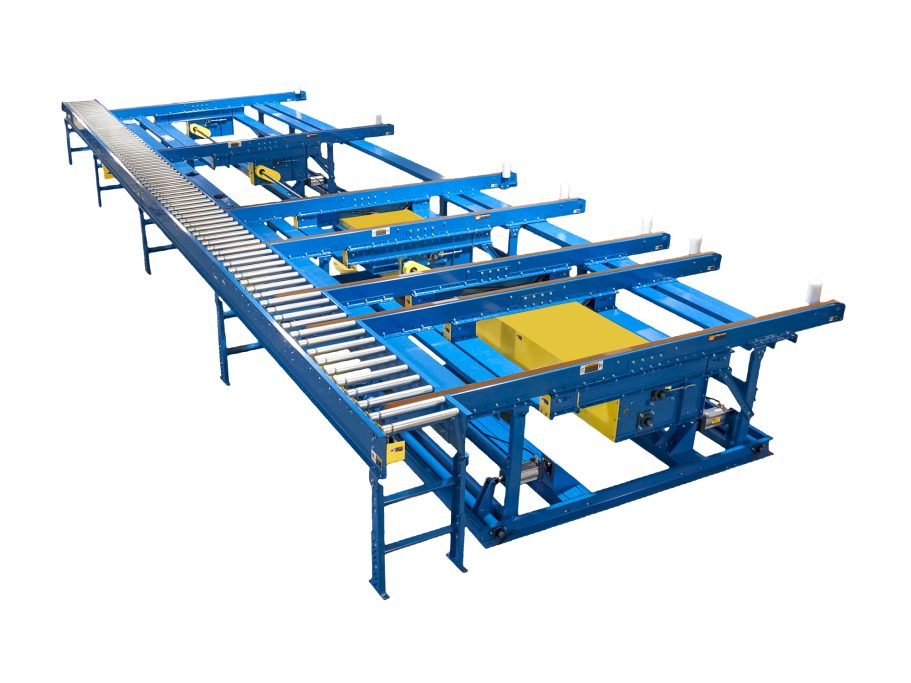

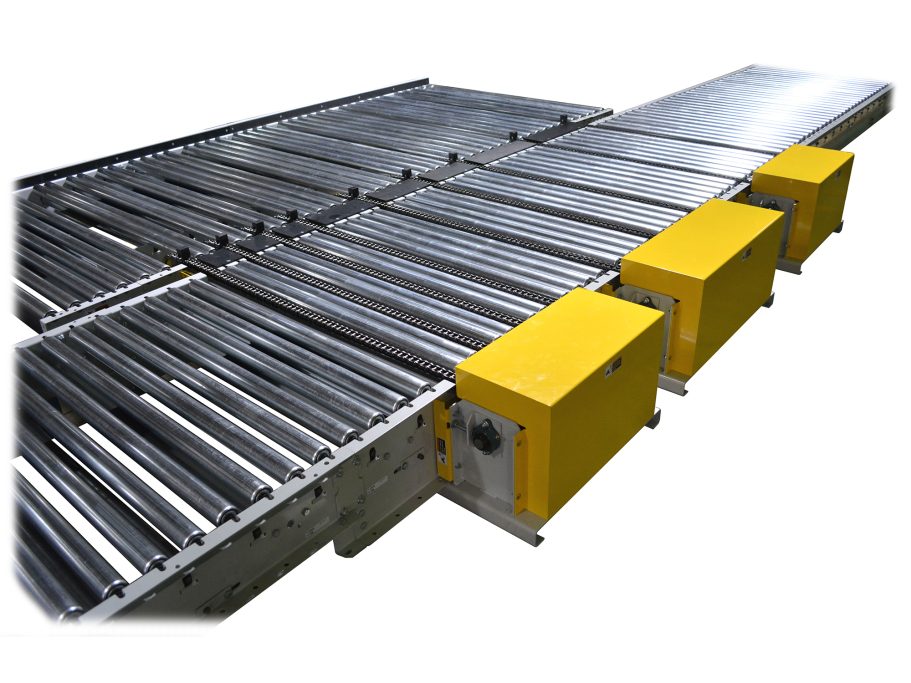

10-Strand 90° Belt Transfer

Designed to transfer various size products, this multi-strand belt transfer is over 6 feet long with strand centerlines ranging from 12″ to 48″. Unit features 2″ wide 3-ply poly #135 brown nitrile roughtop belting with recessed lacing and B-section V-guides molded in center of lower FS side of belt for tracking. Transfer features pivot type lift and mounts into model 196LR belt driven live roller with 6″ wide belting. Optional blue powder paint and optional yellow powder paint on chain guards/covers shown. Also, orange roller covering is 1/8″ thick Kastalon, which protects product when conveyed on model 196LR. ref#355305-355306

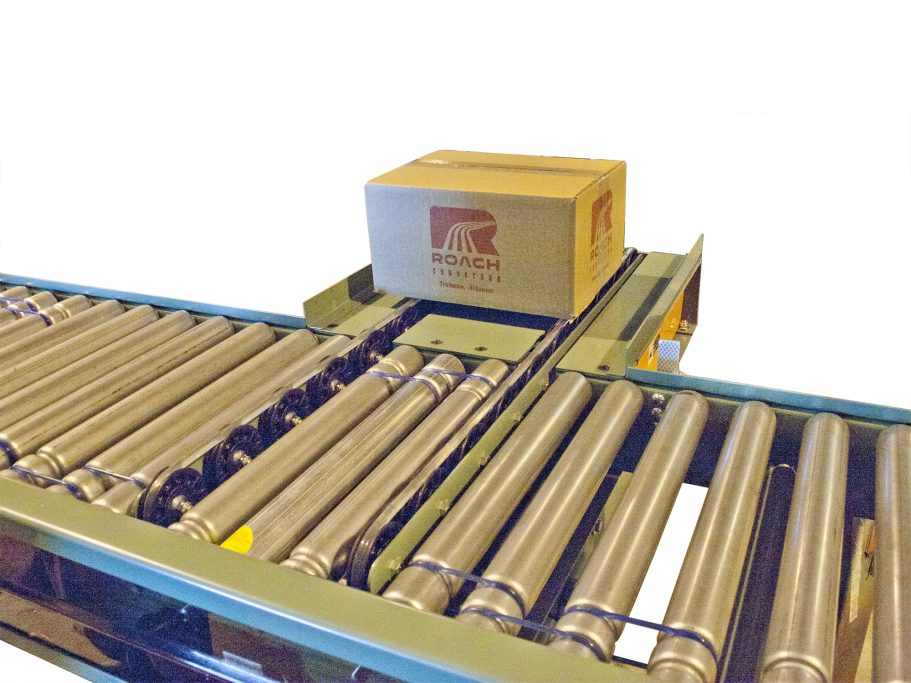

3-Strand 90° Slat Transfer with 3509CDLR

This specialty transfer conveyor transfers products at 90-degrees. The transfer is mounted below the top of the conveyor roller and is raised pneumatically to move the strands above the top of chain guard to transfer product 90 degrees. The transfer is reversible and includes a driven relief section to bridge the transition to chain conveyor, which provides the conveyed product a smooth transition.

Motor Driven Roller CDLR Gravity Transfer

This unit is ideal for handling pallets as they are being loaded or unloaded. The 24v Motor Driven Rollers allow for low profile design and easy operator control. The 192 Gravity pop-up transfer makes it possible to manually transition between conveyor lines.

ref#529402

Motor Driven Roller CDLR Gravity Transfer

This unit is ideal for handling pallets as they are being loaded or unloaded. The 24v Motor Driven Rollers allow for low profile design and easy operator control. The 192 Gravity pop-up transfer makes it possible to manually transition between conveyor lines.

ref#529402