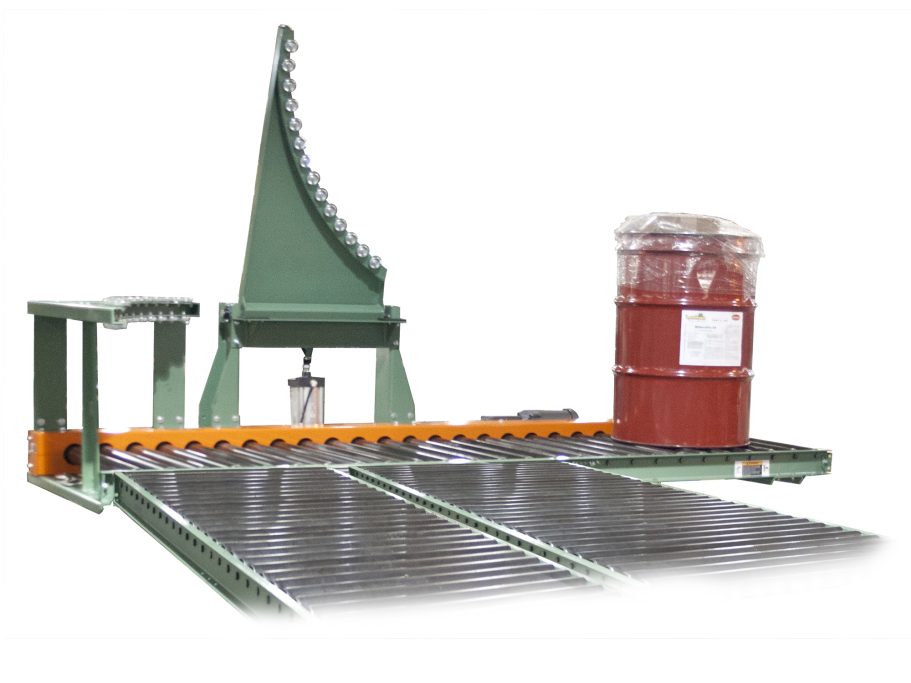

BARREL HANDLING

Barrel handling conveyors are engineered for the controlled movement, rotation, and diverting of cylindrical containers such as drums, barrels, and kegs. These systems are commonly used where containers must be oriented, indexed, or transferred between process steps without manual handling. Designs typically rely on driven rollers, chain driven live rollers, or friction surfaces that engage the curved profile of the barrel while maintaining stability and predictable motion.

Barrel diverting conveyors operate by selectively redirecting barrels from a main conveyor path to secondary lanes or workstations. This is achieved through angled roller arrangements, powered diverters, or lift and transfer mechanisms that rotate or laterally shift the barrel. The equipment is built to manage high unit weights, uneven load distribution, and surface conditions such as steel, plastic, or fiber drums. Construction focuses on durability, repeatable motion, and compatibility with upstream and downstream material handling equipment.

Applications

- Diverting barrels to filling or emptying stations

- Rotating drums for mixing or agitation processes

- Accumulating barrels prior to palletizing or stretch wrapping

- Transferring drums between parallel conveyor lines

Industries

- Chemical processing and bulk materials

- Food and beverage production

- Paints, coatings, and adhesives

- Pharmaceutical and specialty manufacturing

796CALR | Barrel Diverting Pneumatic Arms

This 796CALR with 90° pneumatic diverter arms is designed to move 30 gallon barrels down the main product line. The left arm lowers to divert barrels down a secondary line, while the right arm lowers to divert barrels from the secondary line back onto the main product line. Both arms can be raised to send barrels straight through the main product line.