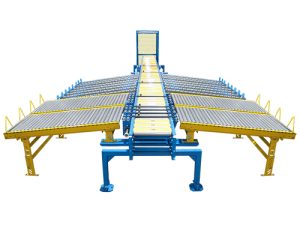

638CALR is ideally suited for horizontal conveying of items where transfers, side loading or unloading, or temporary accumulation is required in light duty applications or when small items are conveyed requiring close standard roller spacing.

638CALR is ideally suited for horizontal conveying of items where transfers, side loading or unloading, or temporary accumulation is required in light duty applications or when small items are conveyed requiring close standard roller spacing.

| Specifications | TREAD ROLLERS: 1-3/8″ dia. x 18 ga. galvanized steel, model 138G with 5/16″ hex. PRESSURE ROLLERS: 1-3/8″ dia. x 18 ga. galvanized steel, model 138G with 5/16″ hex. RETURN ROLLERS: 1-3/8″ dia. x 18 ga. galvanized steel, model 138G with 5/16″ hex, adjustable. BELTING: 6″ wide black PVC-120 COS. CENTER DRIVE: Reversible drive w/ 24″ integral belt take-up. Specify location. DRIVE PULLEY: 4″ dia. with 1-3/16″ dia. shaft or 8″ dia. with 1-7/16″ dia. shaft; both crowned and fully lagged. END PULLEY: 4″ dia., crowned, with 1-3/16″ dia. shaft. SPEED: 60 FPM, constant. MOTOR DRIVE: 1/3 HP, 230/460/3, 60 cycle, ODP right angle gear motor. BED: 6″ x 1-1/2″ x 12 ga. channel frame slotted for tread rollers to pop-out. When unit is installed at 7′-0″ elevation or higher, rollers must be retained in conveyor frame. Specify desired elevation. Bed sections attached with couplings and floor supports. SQUARING RODS: Adjustable rods on underside of bed allow frame to be squared for improved belt tracking and are standard on all units over 30′. FLOOR SUPPORTS: Optional BEARINGS: All pulley bearings are precision, heavy duty, lubricated, ball bearing units with cast iron housings. ROLLER CHAIN: Drive pulley is driven by No. 50 roller chain for 1-1/2 HP or less and No. 60 chain on larger drives. Chain take-up provided on motor base. ELECTRICAL CONTROLS: Optional |

|---|

638CALR

638CALR is ideally suited for horizontal conveying of items where transfers, side loading or unloading, or temporary accumulation is required in light duty applications or when small items are conveyed requiring close standard roller spacing.

| Specifications | TREAD ROLLERS: 1-3/8″ dia. x 18 ga. galvanized steel, model 138G with 5/16″ hex. PRESSURE ROLLERS: 1-3/8″ dia. x 18 ga. galvanized steel, model 138G with 5/16″ hex. RETURN ROLLERS: 1-3/8″ dia. x 18 ga. galvanized steel, model 138G with 5/16″ hex, adjustable. BELTING: 6″ wide black PVC-120 COS. CENTER DRIVE: Reversible drive w/ 24″ integral belt take-up. Specify location. DRIVE PULLEY: 4″ dia. with 1-3/16″ dia. shaft or 8″ dia. with 1-7/16″ dia. shaft; both crowned and fully lagged. END PULLEY: 4″ dia., crowned, with 1-3/16″ dia. shaft. SPEED: 60 FPM, constant. MOTOR DRIVE: 1/3 HP, 230/460/3, 60 cycle, ODP right angle gear motor. BED: 6″ x 1-1/2″ x 12 ga. channel frame slotted for tread rollers to pop-out. When unit is installed at 7′-0″ elevation or higher, rollers must be retained in conveyor frame. Specify desired elevation. Bed sections attached with couplings and floor supports. SQUARING RODS: Adjustable rods on underside of bed allow frame to be squared for improved belt tracking and are standard on all units over 30′. FLOOR SUPPORTS: Optional BEARINGS: All pulley bearings are precision, heavy duty, lubricated, ball bearing units with cast iron housings. ROLLER CHAIN: Drive pulley is driven by No. 50 roller chain for 1-1/2 HP or less and No. 60 chain on larger drives. Chain take-up provided on motor base. ELECTRICAL CONTROLS: Optional |

|---|

638CALR